RPMs are nice sounding --- while they last! that 6XL is really a 3S max motor. then it would turn closer to 30k rpms and probably even be more efficient.

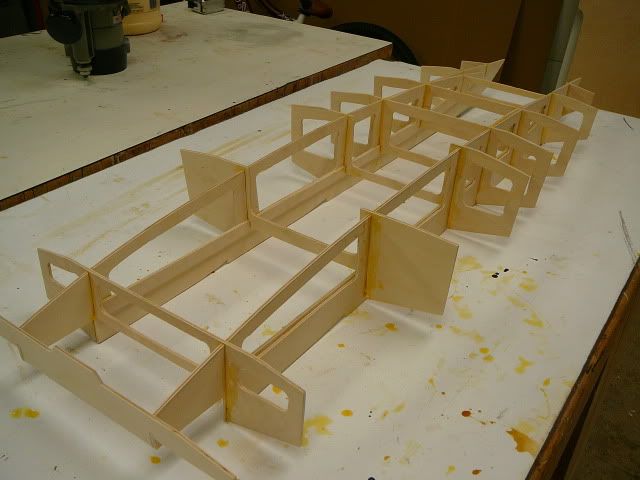

36inch twin cat build

Collapse

X

-

-

I hope you didn't get too many fingers incorporated into the framework with all that glue..."Look good doin' it"

See the fleetComment

-

Lookin good. I would recommend mountaing the motors before skinning. Make sure they fit and assess any problems before they become skinned problems. Then skin the sides, base and then deck (is how I do it). You could remount the motors before you do the topside to be sure you will have enough room.

what motor mounts are you using?

For skinning, either use 1/16" or 3/32" ply or 1/8" thick balsa covered with 1/64" thin ply. balsa grain goes shortways and ply go longways - except for the deck where you go longways for both. then glass it because I have a feeling you will be going very fast.

Hatch area looks good, might need to make some framing to support it.

there are several versions of these plans, Lomdel has a twin motor set and I have a slightly different (single motor) set."Look good doin' it"

See the fleetComment

-

so the way to make the hatch larger will be fine? and by ''glass it'' do you mean fibre glass?? and do i do the inside or the outside?Lookin good. I would recommend mountaing the motors before skinning. Make sure they fit and assess any problems before they become skinned problems. Then skin the sides, base and then deck (is how I do it). You could remount the motors before you do the topside to be sure you will have enough room.

what motor mounts are you using?

For skinning, either use 1/16" or 3/32" ply or 1/8" thick balsa covered with 1/64" thin ply. balsa grain goes shortways and ply go longways - except for the deck where you go longways for both. then glass it because I have a feeling you will be going very fast.

Hatch area looks good, might need to make some framing to support it.

there are several versions of these plans, Lomdel has a twin motor set and I have a slightly different (single motor) set.SUPERVEE 27 37'' TWIN CAT

37'' TWIN CATComment

-

I spray the framework with 3-5 coats of polyurethane to protect in the eventual case of hull flooding. Then I skin side and base. Then I dribble that window insulation "GreatStuff" in the front chambers (a third full as it expands a lot!). then trim and sand to the shape you want the deck. then after you get this and all your hardware figured out, then the deck.

THEN I like to seal up the hull again with polyurethane (brush on this time). I then test the hull and make sure I don't need to do significant bondo work. When satisfied, then go get some slow cure Epoxy (top coat I think its called) and medium weight glass cloth. Do small pieces of cloth as opposed to larger. Once this is all done, sand - but not too much - and check that you don't need to do any filling with bondo.

I like to add the strakes after glassing so I don't get any stupid lumps. then sand, prime and paint."Look good doin' it"

See the fleetComment

-

Watch this video. Look at how the guy mounted his motors! I've never seen it done that way but it seems to work and work well!

Mini Cat Racing USA

www.minicatracingusa.comComment

-

that is very coolWatch this video. Look at how the guy mounted his motors! I've never seen it done that way but it seems to work and work well!

http://www.youtube.com/watch?v=59cn5...eature=relatedSUPERVEE 27 37'' TWIN CAT

37'' TWIN CATComment

Comment