Sold my original Rivercat  figured it was time to let it go to a good home and build another one later (yea that lasted about 3 days)as I've collected a few hulls (I love this little cat, what can I say?). I go up in the attic to grab the cheetah I'm starting on and grab a Rivercat to sit on my top shelf (I was feeling lonely lol). It sat up there for about a day or two before I got it down and started the inlay on it. Ok, enough about that. My goal for this cat is to make it as strong, nice and as fast as my skills will allow. I'm going to use everything I've learned and apply it to this. I'll be going back and forth on this between 4 other builds. I'll be posting one more different build soon. I encourage any ideas or discussion through this build, in my opinion that's part of the fun and keeps me motivated....so by all means, have at it.

figured it was time to let it go to a good home and build another one later (yea that lasted about 3 days)as I've collected a few hulls (I love this little cat, what can I say?). I go up in the attic to grab the cheetah I'm starting on and grab a Rivercat to sit on my top shelf (I was feeling lonely lol). It sat up there for about a day or two before I got it down and started the inlay on it. Ok, enough about that. My goal for this cat is to make it as strong, nice and as fast as my skills will allow. I'm going to use everything I've learned and apply it to this. I'll be going back and forth on this between 4 other builds. I'll be posting one more different build soon. I encourage any ideas or discussion through this build, in my opinion that's part of the fun and keeps me motivated....so by all means, have at it.

Here's a parts list:

Hull: 32" fightercat carbon fiber Rivercat

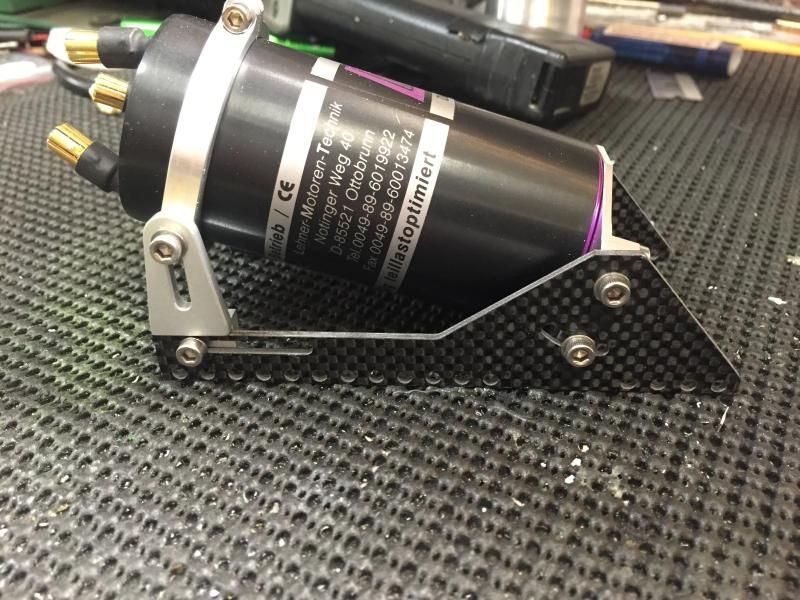

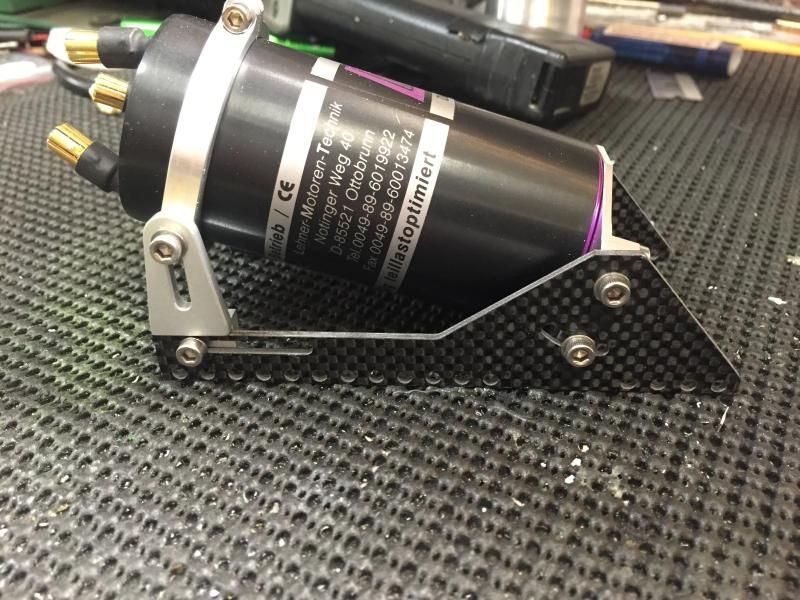

Motor: lehner 2250

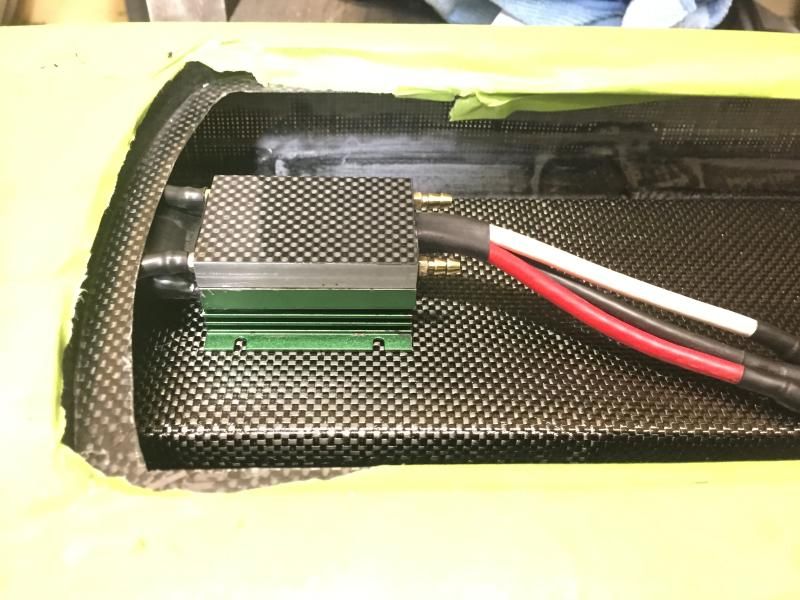

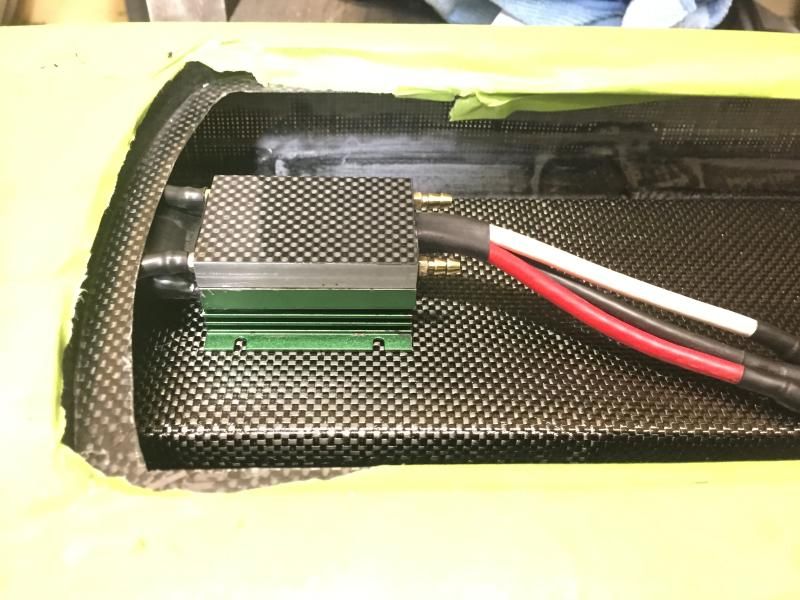

Esc: castle 8s capable mamba xl2 converted to water cooled

Cap bank: yes of course

Collet: mbp 8mm x .187

Flex: aeromarine .187

Servo: billet spectrum waterproof (new not released yet but on preorder)

Servo linkage: stainless heavy duty rod, polished

Batt connectors: castle green 6.5mm

Batts: revo 427's 5500 70c

Motor mount: kintec adjustable sliding

The inlay is a tad different that I usually do. One layer has always faired good enough and held up well. I decided to do one regular layer on the tunnel only and then go over the whole thing with a heavier layer of honey comb cf.

First layer:

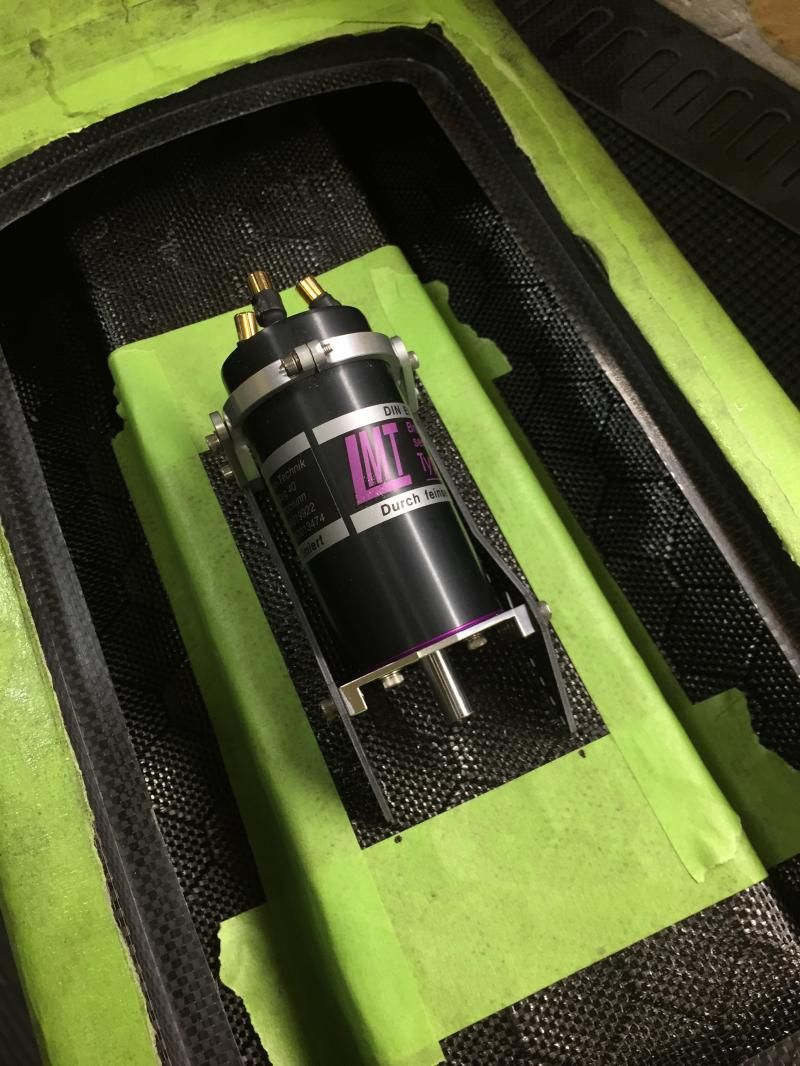

Motor mount with a 2260 in it for mockup (2250 hasn't got here yet)

[/URL]

[/URL]

figured it was time to let it go to a good home and build another one later (yea that lasted about 3 days)as I've collected a few hulls (I love this little cat, what can I say?). I go up in the attic to grab the cheetah I'm starting on and grab a Rivercat to sit on my top shelf (I was feeling lonely lol). It sat up there for about a day or two before I got it down and started the inlay on it. Ok, enough about that. My goal for this cat is to make it as strong, nice and as fast as my skills will allow. I'm going to use everything I've learned and apply it to this. I'll be going back and forth on this between 4 other builds. I'll be posting one more different build soon. I encourage any ideas or discussion through this build, in my opinion that's part of the fun and keeps me motivated....so by all means, have at it.

figured it was time to let it go to a good home and build another one later (yea that lasted about 3 days)as I've collected a few hulls (I love this little cat, what can I say?). I go up in the attic to grab the cheetah I'm starting on and grab a Rivercat to sit on my top shelf (I was feeling lonely lol). It sat up there for about a day or two before I got it down and started the inlay on it. Ok, enough about that. My goal for this cat is to make it as strong, nice and as fast as my skills will allow. I'm going to use everything I've learned and apply it to this. I'll be going back and forth on this between 4 other builds. I'll be posting one more different build soon. I encourage any ideas or discussion through this build, in my opinion that's part of the fun and keeps me motivated....so by all means, have at it. Here's a parts list:

Hull: 32" fightercat carbon fiber Rivercat

Motor: lehner 2250

Esc: castle 8s capable mamba xl2 converted to water cooled

Cap bank: yes of course

Collet: mbp 8mm x .187

Flex: aeromarine .187

Servo: billet spectrum waterproof (new not released yet but on preorder)

Servo linkage: stainless heavy duty rod, polished

Batt connectors: castle green 6.5mm

Batts: revo 427's 5500 70c

Motor mount: kintec adjustable sliding

The inlay is a tad different that I usually do. One layer has always faired good enough and held up well. I decided to do one regular layer on the tunnel only and then go over the whole thing with a heavier layer of honey comb cf.

First layer:

Motor mount with a 2260 in it for mockup (2250 hasn't got here yet)

[/URL]

[/URL]

Comment