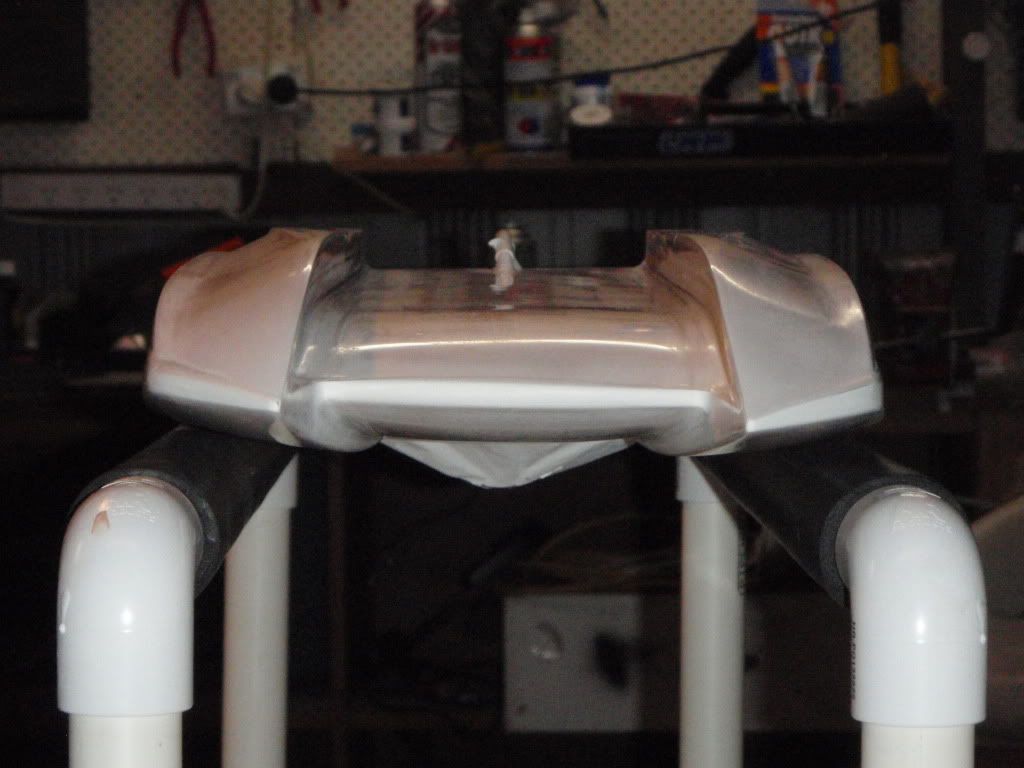

Well I've been working away now for a few weeks, I only get a few hours at night to play around so it takes a while but I'm just prepping the hull for painting and I thought I'd get my build thread underway whilst the primer dry's.

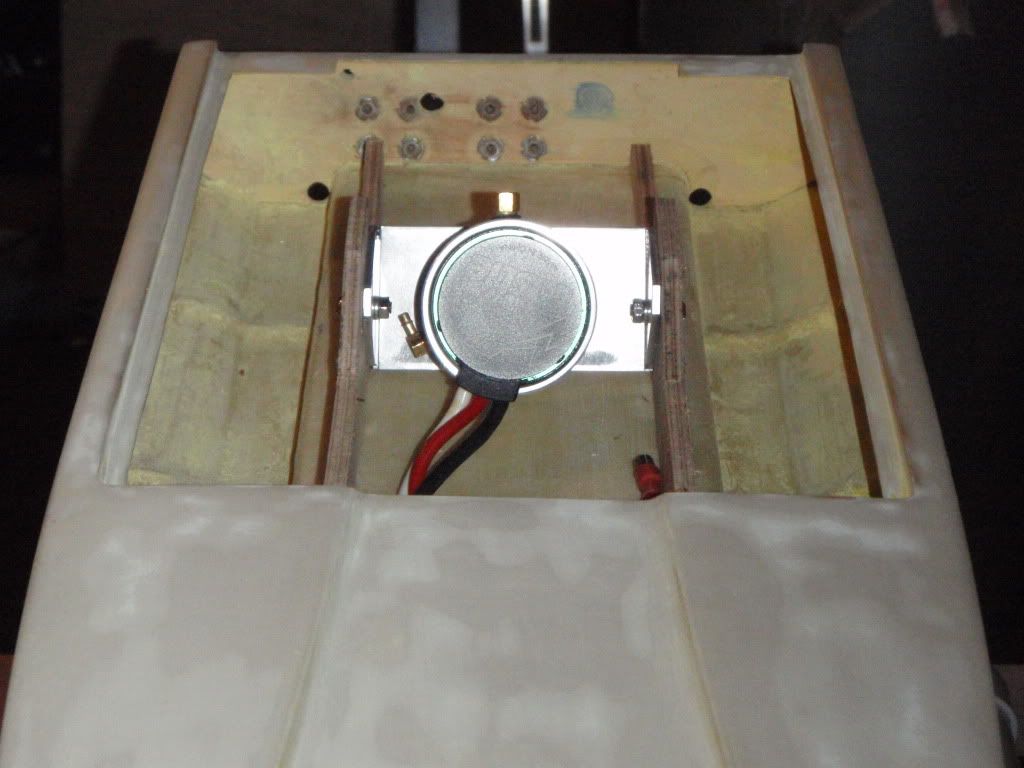

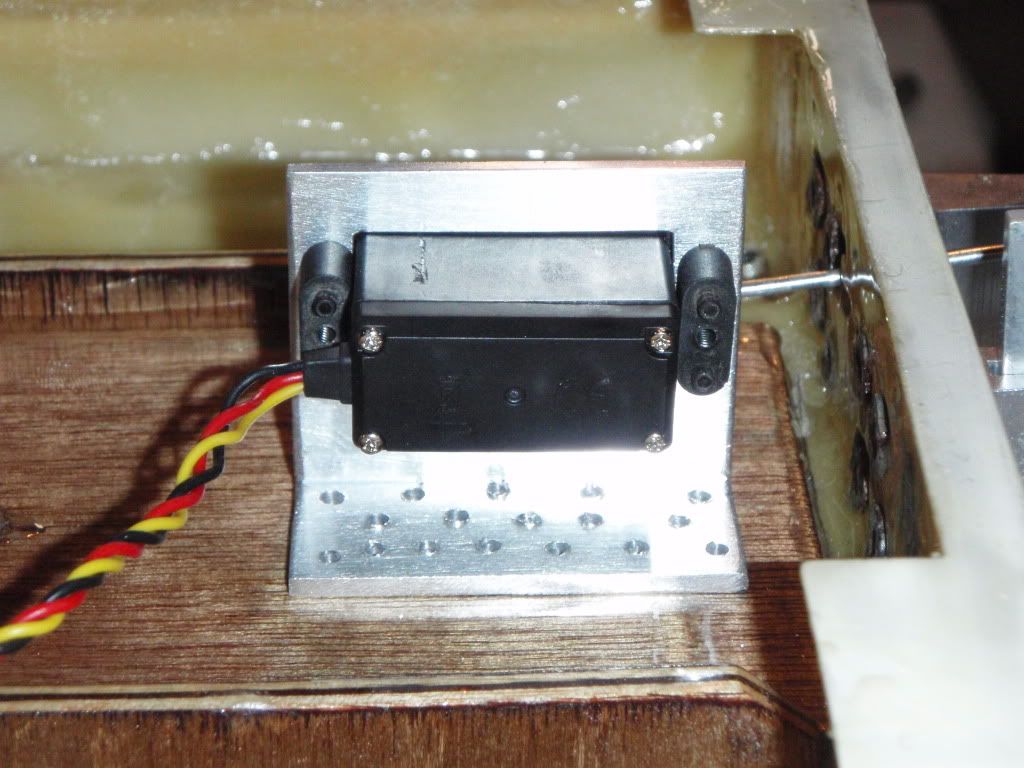

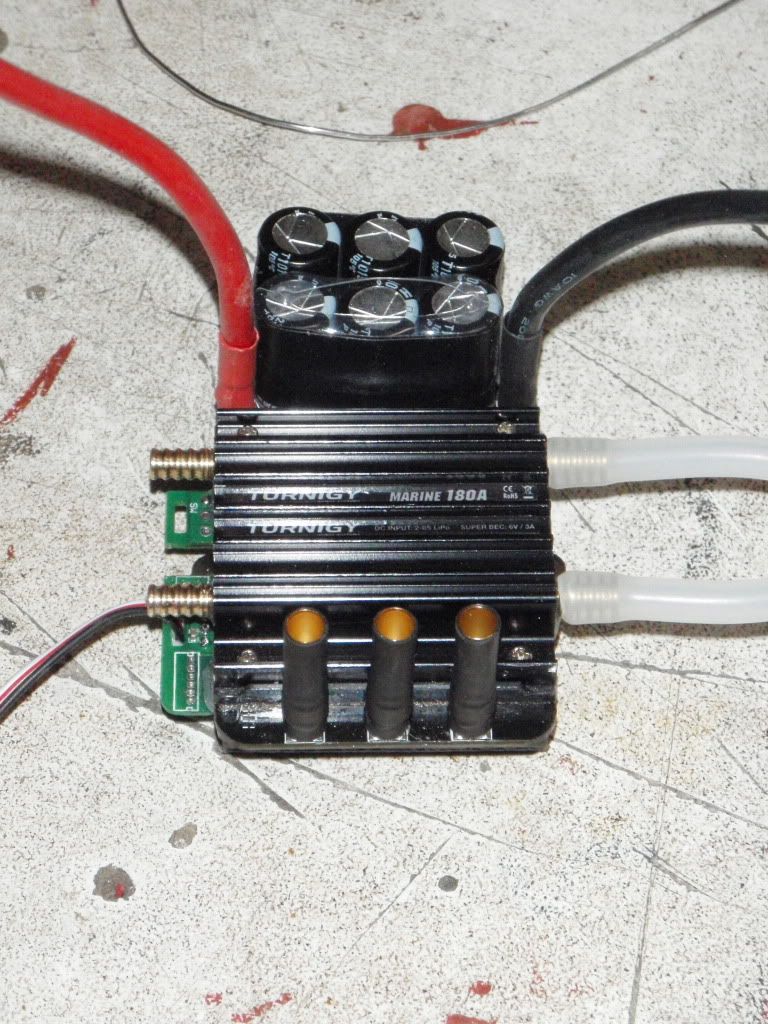

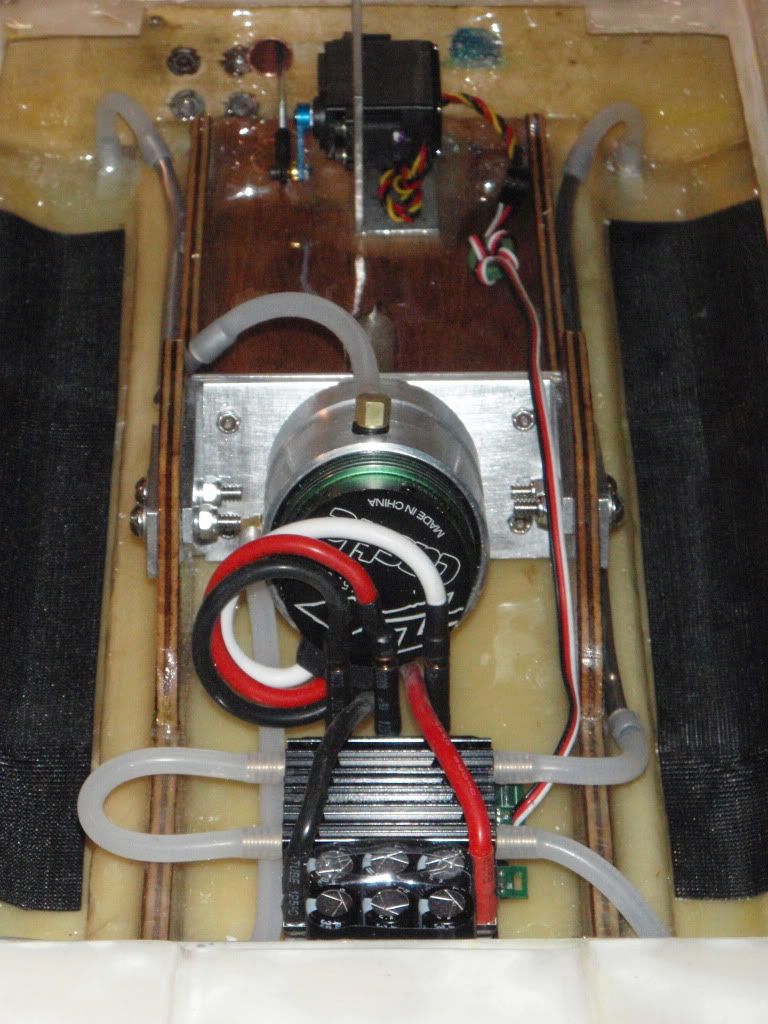

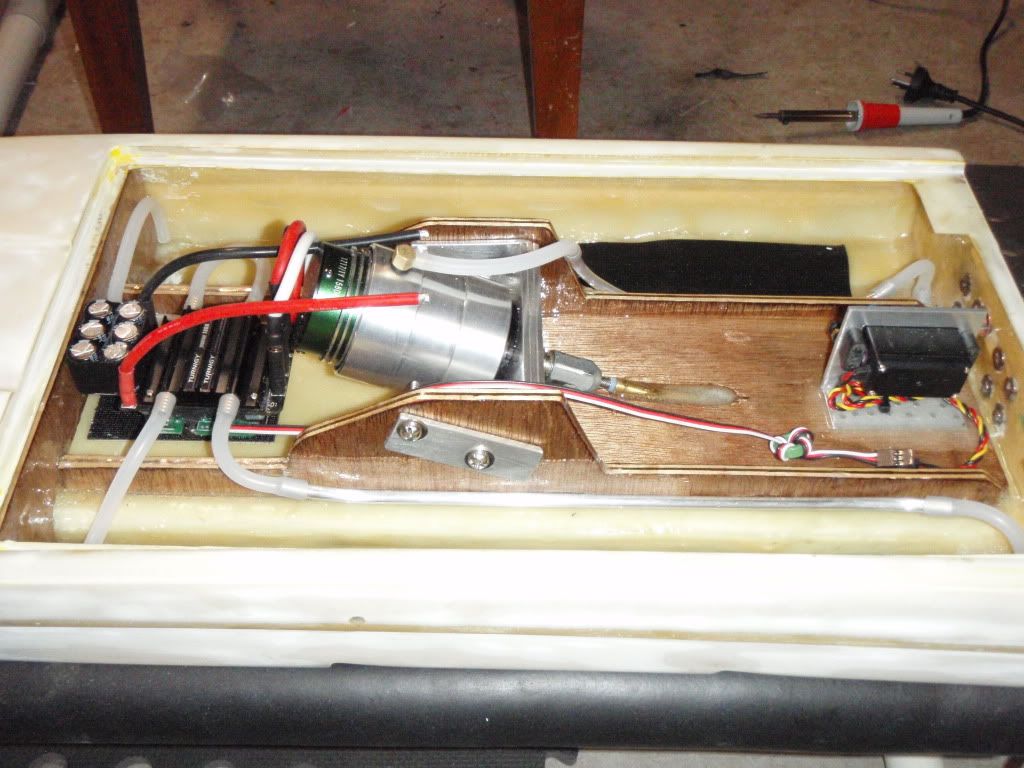

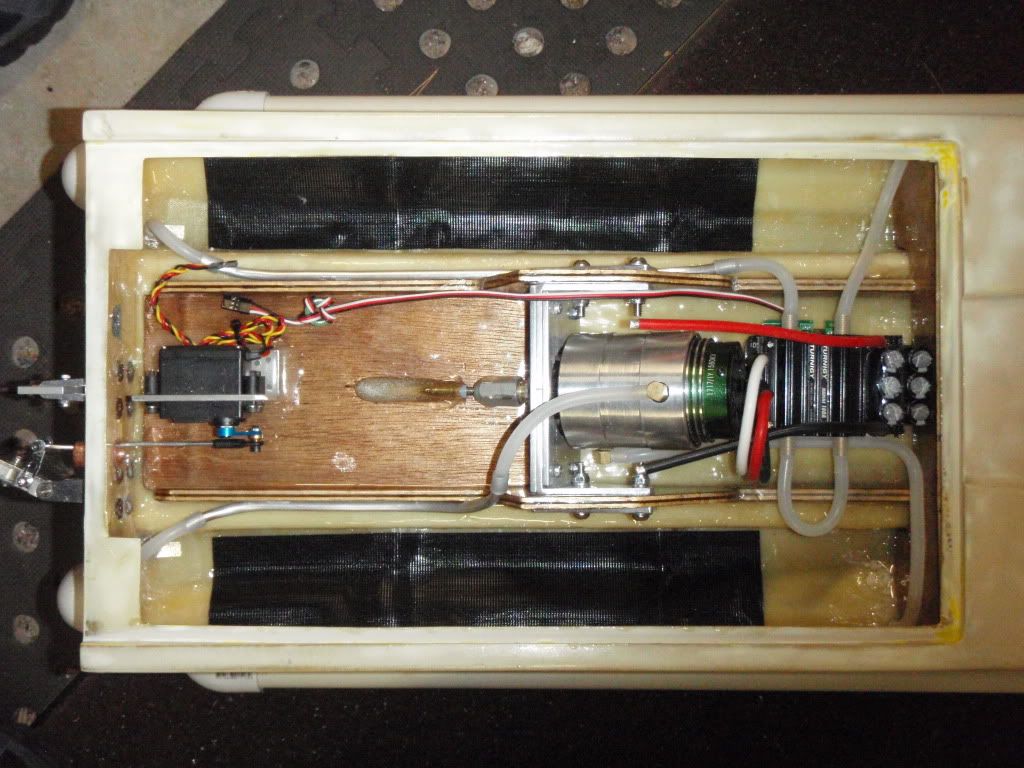

For this build I'm starting with a "water damaged" Aeromarine mean machine. I'll be putting in a castle 1717, turnigy 180 amp esc, hitec hs-5645 servo and a spektrum mr300 rx. I plan on running 6s2p 10000mAh with probably a M445 and maybe a m447 for my driving but this build is more for my boy's to learn on. For the kids, I plan on running 4s2p 10000mAh with a X442 thats had the tongues removed, I'm hoping this will slow it down to a reasonable speed for learning, keep temps down and increase run times.

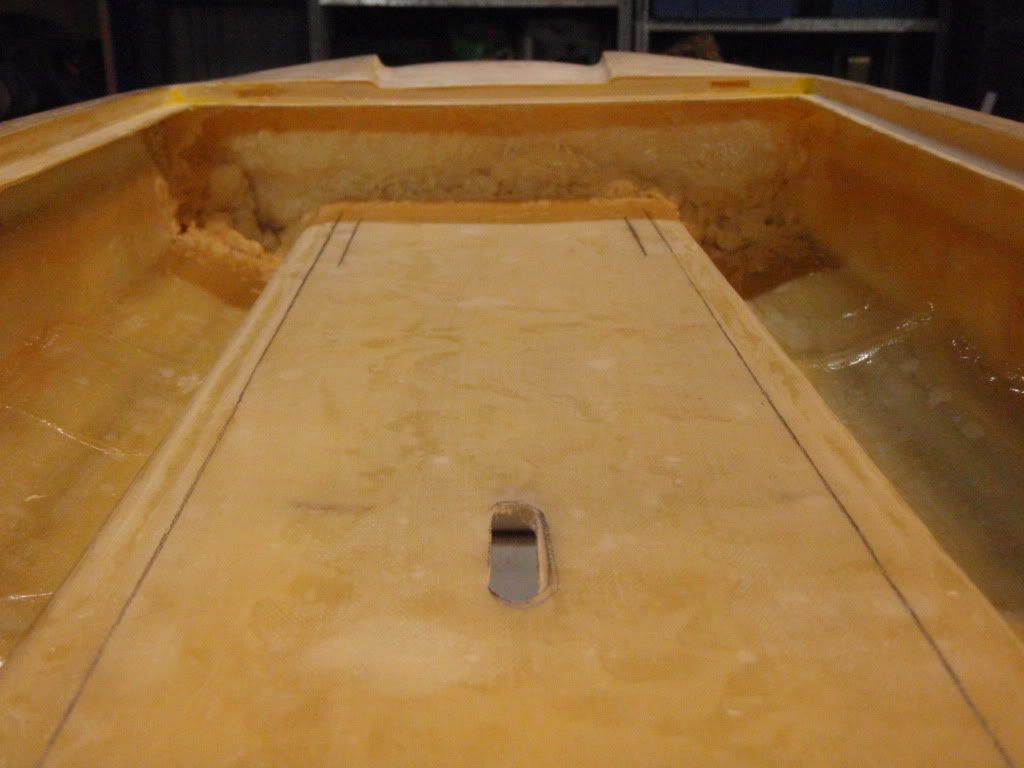

I started by stripping down the nitro rtr, it suprised me how easy everything come out. The "water damage" hadn't effected too much, all the screws, push rod and connectors were rusted but otherwise things were pretty good.

For this build I'm starting with a "water damaged" Aeromarine mean machine. I'll be putting in a castle 1717, turnigy 180 amp esc, hitec hs-5645 servo and a spektrum mr300 rx. I plan on running 6s2p 10000mAh with probably a M445 and maybe a m447 for my driving but this build is more for my boy's to learn on. For the kids, I plan on running 4s2p 10000mAh with a X442 thats had the tongues removed, I'm hoping this will slow it down to a reasonable speed for learning, keep temps down and increase run times.

I started by stripping down the nitro rtr, it suprised me how easy everything come out. The "water damage" hadn't effected too much, all the screws, push rod and connectors were rusted but otherwise things were pretty good.

Comment