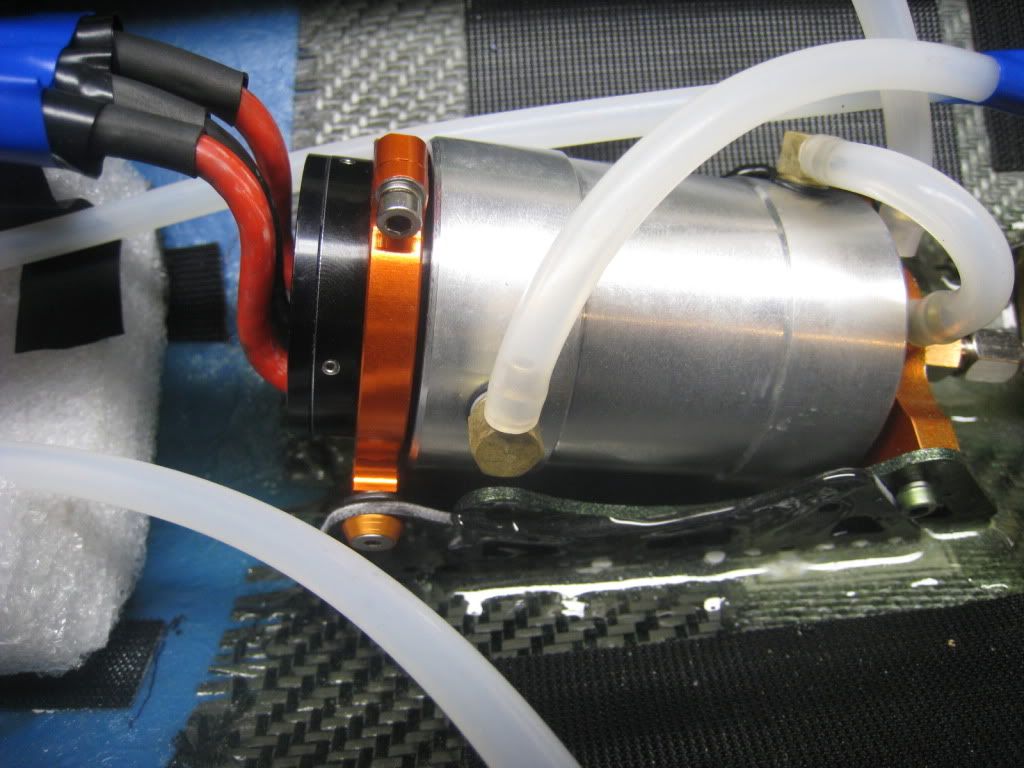

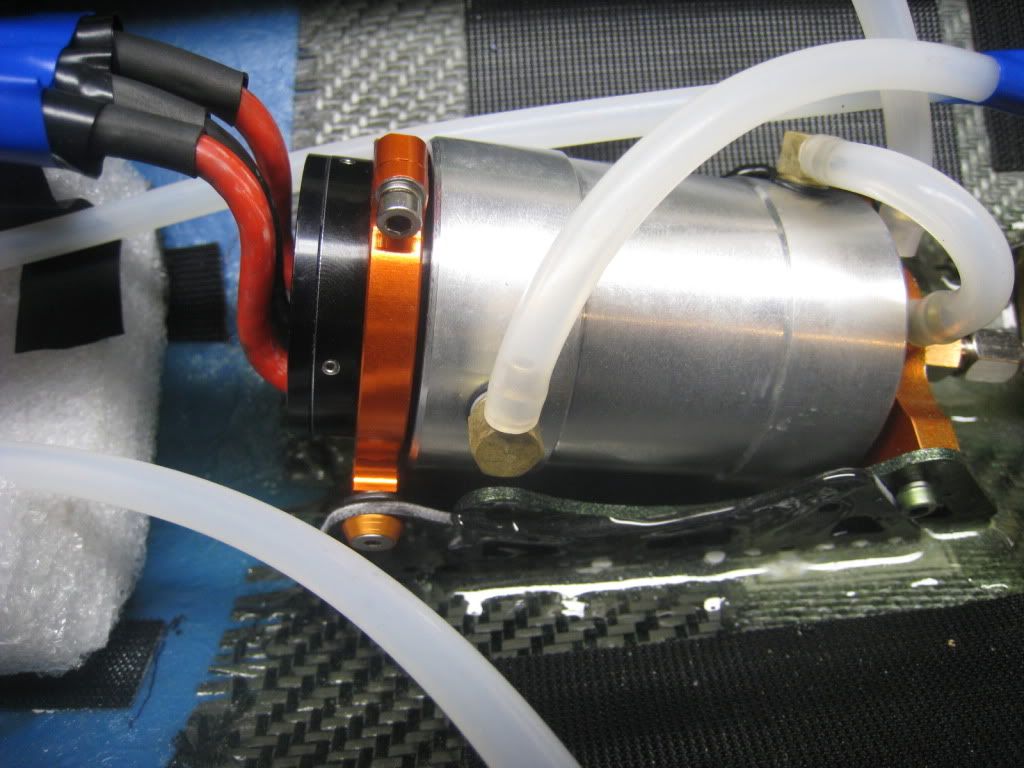

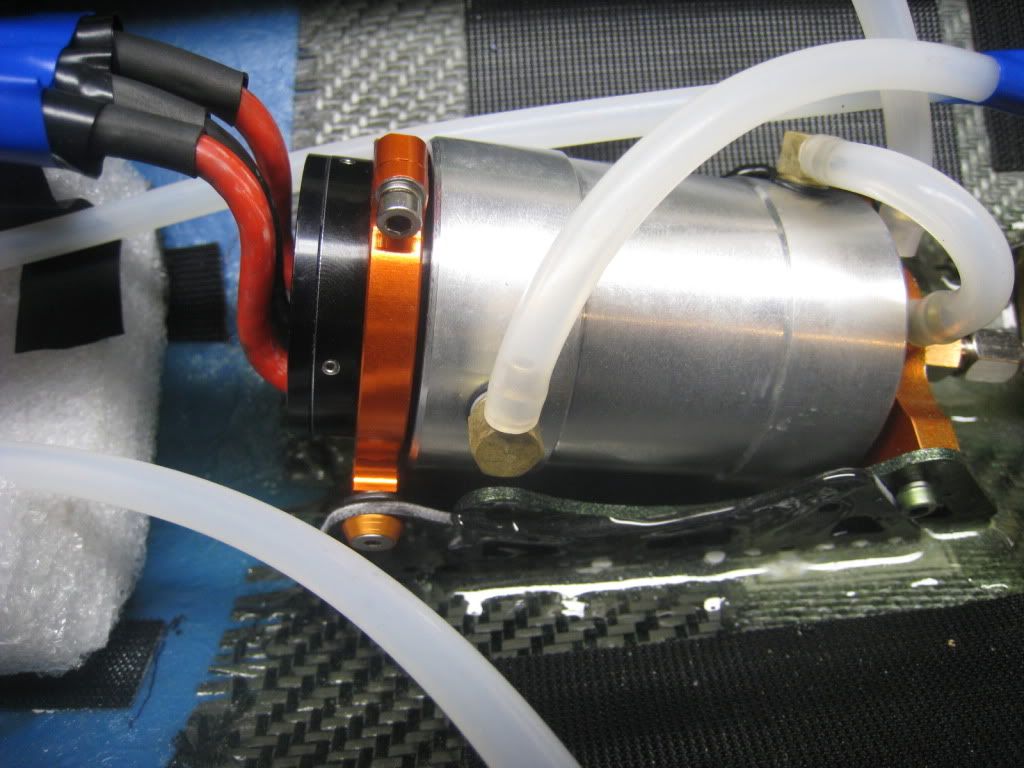

Got the Neu 1521 installed with new jacket, and 40mm rear mount. Had to do a little epoxying. Also, does my drive dog/ stinger gap look ok?

: http://forums.offshoreelectrics.com/...hp?albumid=294

: http://forums.offshoreelectrics.com/...hp?albumid=294 : http://forums.offshoreelectrics.com/...hp?albumid=294

: http://forums.offshoreelectrics.com/...hp?albumid=294

Comment