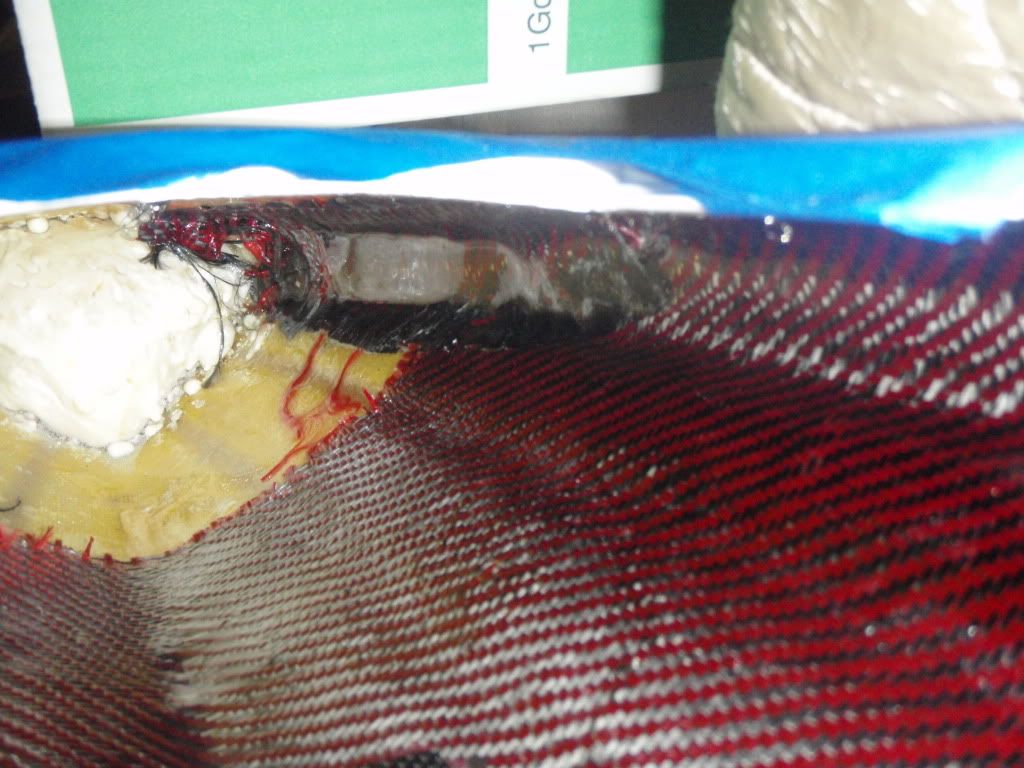

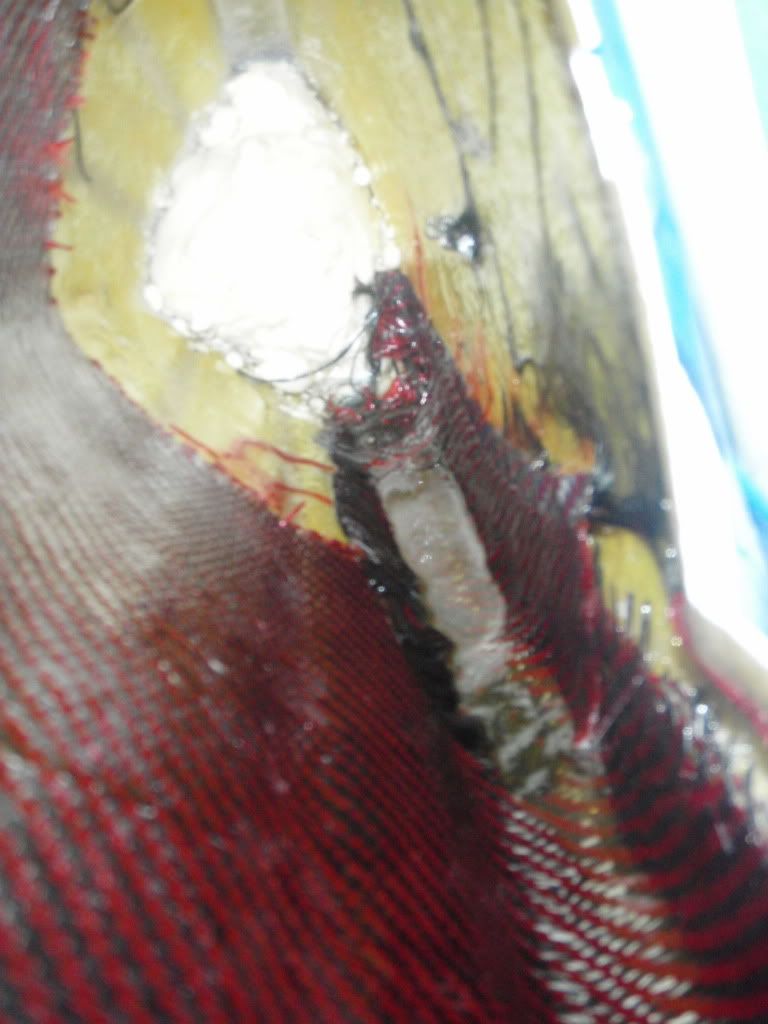

Last night I began to strip out my df35 to get it ready for a rebuild. I plan on getting the hull back to scratch, filling most of the drilled holes and starting all over again as this was my first build nearly a year ago, back when I was nervous at the thought of drilling a hole in the hull. I'm going to have to remove the overweight bodge job motor mount and stuffing tube, sand back and remove all the excess epoxy mess inside the hull thats ungodly thick and remove all the stickers so the hull can be painted.

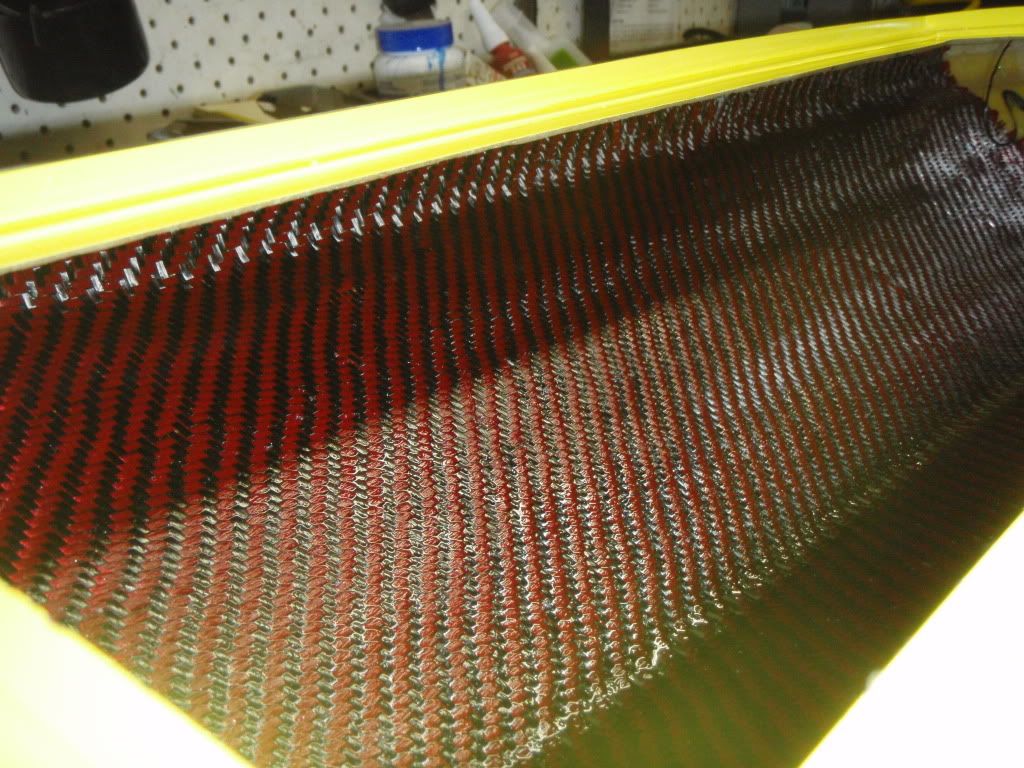

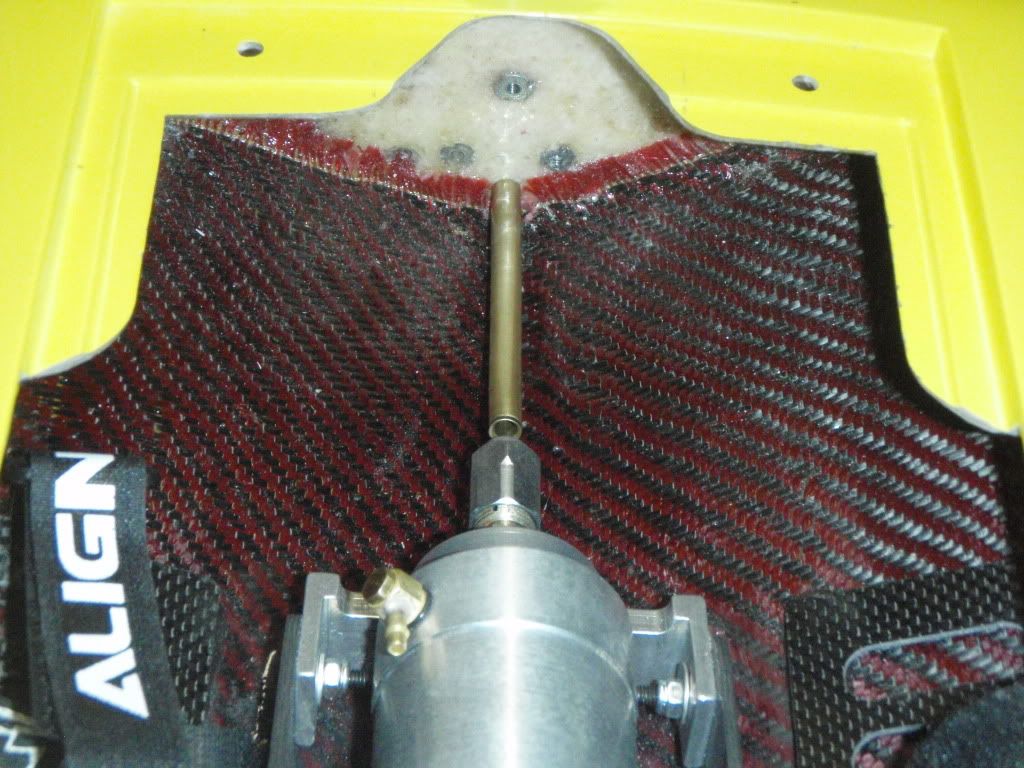

I will lay some carbon/kevlar cloth in the hull and transom, redrill for trim tabs, remove the bottom right hand corner of the rudder bracket so the trim tabs can be fitted a little further apart. I'm thinking a much shorter stuffing tube and making more room for the batteries so it'll stop running a tad wet. I recon I'll paint it up similar to my Titan 29 and DF29, this way I can have all my mono's in a bit of a team color theme.

New motor will be a Neu 1527 1.5d 1500kv, I'll keep the sf240 speedo in there but allow the esc mount to change out to a t180 if need be and it'll be ran with 6s2p 45-90c 10000mAh nano tech lipo's. I'm thinking a m545, m447, x548 with the tongues removed or a x646, my goal remains the same, 100kph / 62mph.

I will lay some carbon/kevlar cloth in the hull and transom, redrill for trim tabs, remove the bottom right hand corner of the rudder bracket so the trim tabs can be fitted a little further apart. I'm thinking a much shorter stuffing tube and making more room for the batteries so it'll stop running a tad wet. I recon I'll paint it up similar to my Titan 29 and DF29, this way I can have all my mono's in a bit of a team color theme.

New motor will be a Neu 1527 1.5d 1500kv, I'll keep the sf240 speedo in there but allow the esc mount to change out to a t180 if need be and it'll be ran with 6s2p 45-90c 10000mAh nano tech lipo's. I'm thinking a m545, m447, x548 with the tongues removed or a x646, my goal remains the same, 100kph / 62mph.

Comment