Hi, this is my first post here.

I just recently bought aBJ26 on e-bay as a parts boat.I had planned to use the stock drive gear, but when I saw how broken up the U-joint was I realized it would never do.

I bought the Speed master strut and rudder here at OSE. I have several questions.

(1) I have been reading about strut bushings and how to install the strut, and some of it doesn't make sense to me. The model boats I have built in the past used teflon or nylon thrust washers in front of the drive dog. I was under the impression that the thrust from the prop is transferred to the boat via the strut. If that's not the case then the thrust must go up the flex shaft and applied to the motor shaft to drive the boat forward through the water. This doesn't seem right to me.

(2) It looks to me like the bushing is a nice light press fit into the rear of the strut,(flush with the rear) then the .250 brass tube slides in from the front, (how far?) then the Teflon sleeve slides in to butt up against the forward edge of the bushing, and the heat shrink goes on over the brass tube between the existing stuff box(brass tube) and the new piece protruding from the strut.

(3) I had planned on using the existing hole for the rubber boot/servo linkage for the rudder, but it looks like the rudder will need to be mounted lower and to the right?

(4) I bought the brass bullet nut for the prop shaft. Do need to use a lock nut in front of the brass nut?

So, am I wrong about the strut set up? Does anyone have experience with this type of hardware set up? Can you give me some advice? How critical is the rudder height, prop thrust angle? What about adjustability of the strut? Pictures would be awesome!

I know I will have many other questions in the future, but those are the main ones for right now.

I understand the need for grease.

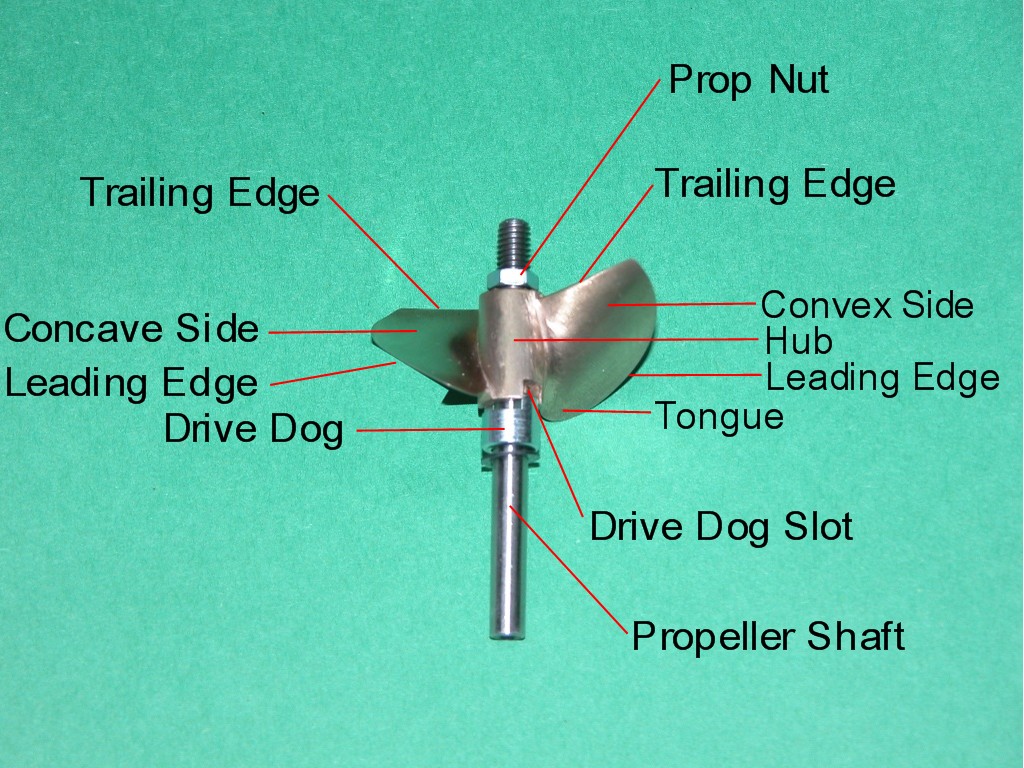

Oh yeah, and one more question; what does it mean to de-tongue a prop?

Thanks in advance, fly2mike

I just recently bought aBJ26 on e-bay as a parts boat.I had planned to use the stock drive gear, but when I saw how broken up the U-joint was I realized it would never do.

I bought the Speed master strut and rudder here at OSE. I have several questions.

(1) I have been reading about strut bushings and how to install the strut, and some of it doesn't make sense to me. The model boats I have built in the past used teflon or nylon thrust washers in front of the drive dog. I was under the impression that the thrust from the prop is transferred to the boat via the strut. If that's not the case then the thrust must go up the flex shaft and applied to the motor shaft to drive the boat forward through the water. This doesn't seem right to me.

(2) It looks to me like the bushing is a nice light press fit into the rear of the strut,(flush with the rear) then the .250 brass tube slides in from the front, (how far?) then the Teflon sleeve slides in to butt up against the forward edge of the bushing, and the heat shrink goes on over the brass tube between the existing stuff box(brass tube) and the new piece protruding from the strut.

(3) I had planned on using the existing hole for the rubber boot/servo linkage for the rudder, but it looks like the rudder will need to be mounted lower and to the right?

(4) I bought the brass bullet nut for the prop shaft. Do need to use a lock nut in front of the brass nut?

So, am I wrong about the strut set up? Does anyone have experience with this type of hardware set up? Can you give me some advice? How critical is the rudder height, prop thrust angle? What about adjustability of the strut? Pictures would be awesome!

I know I will have many other questions in the future, but those are the main ones for right now.

I understand the need for grease.

Oh yeah, and one more question; what does it mean to de-tongue a prop?

Thanks in advance, fly2mike

Comment