Hey gang. Thought I would post up my Revolt. This is my first RC boat and have been following the forum for a few months now trying to learn as much as possible. Very few of my hobbies would be much fun without the help of forums so thanks to OSE and forum staff for running a good one.

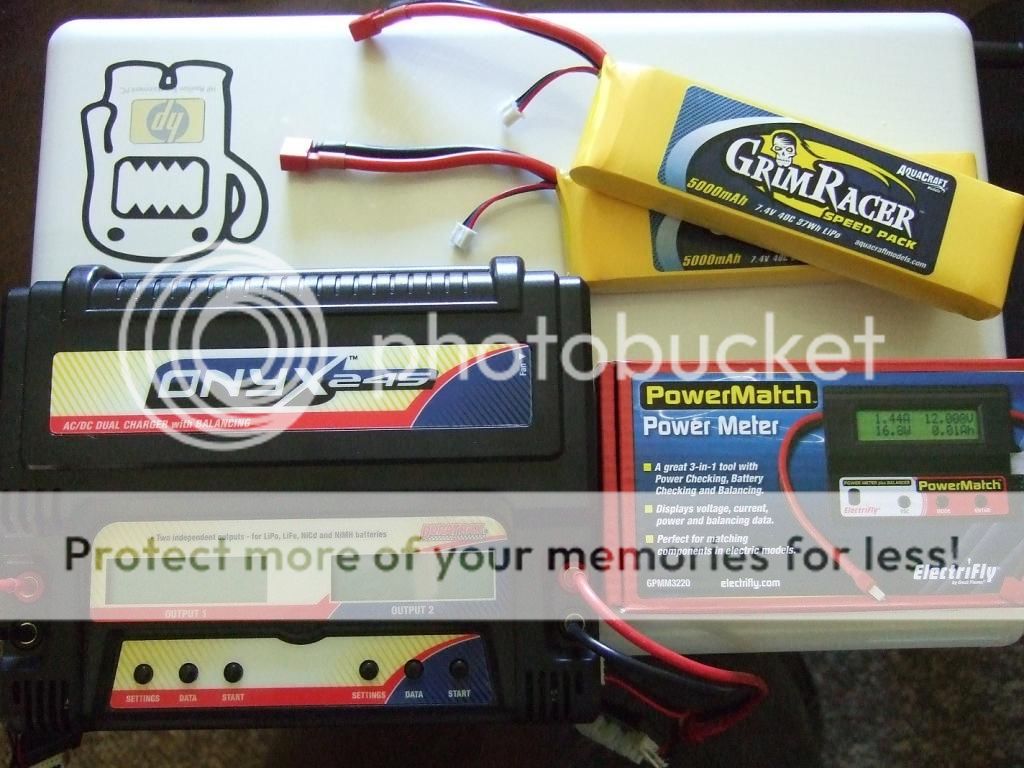

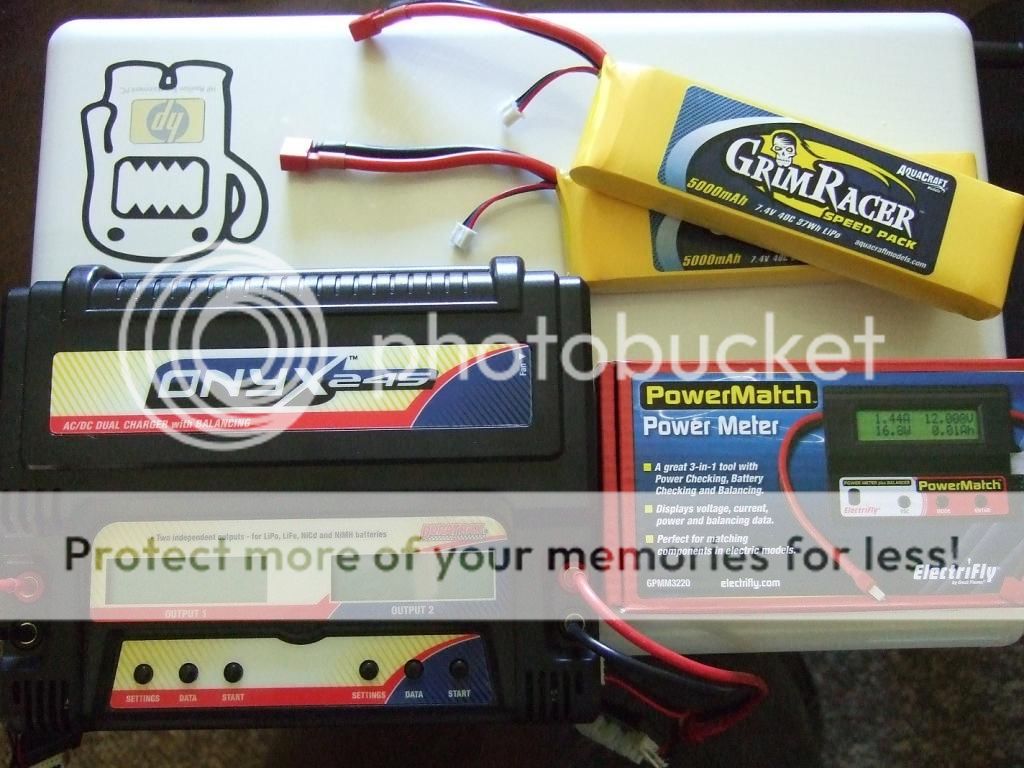

I bought this used as a package off eBay. Came with two Grim Racer 2s 5000mAh 40C lipos, an Onyx 245 charger, and a handy ElectriFly PowerMatch.

So far she has been running well. The flex shaft was very dry and somewhat rusty when I got the boat but I cleaned it up well and treated it to a grease bath, most of the friction was pretty much eliminated right away.

I love the Onyx for the dual charge but it is missing a storage charge mode which is kind of inconvenient.

The PowerMatch has been has been great. So far I pretty much just use it to check voltages and power levels which helps me determine run times and what capacity to store the batteries at.

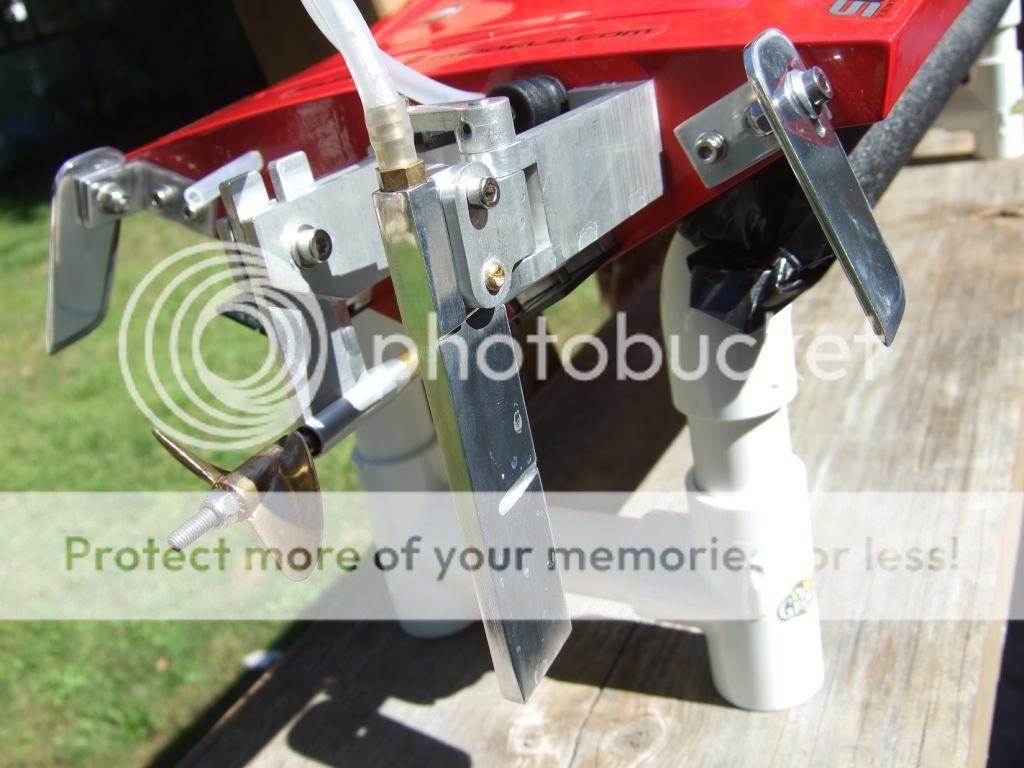

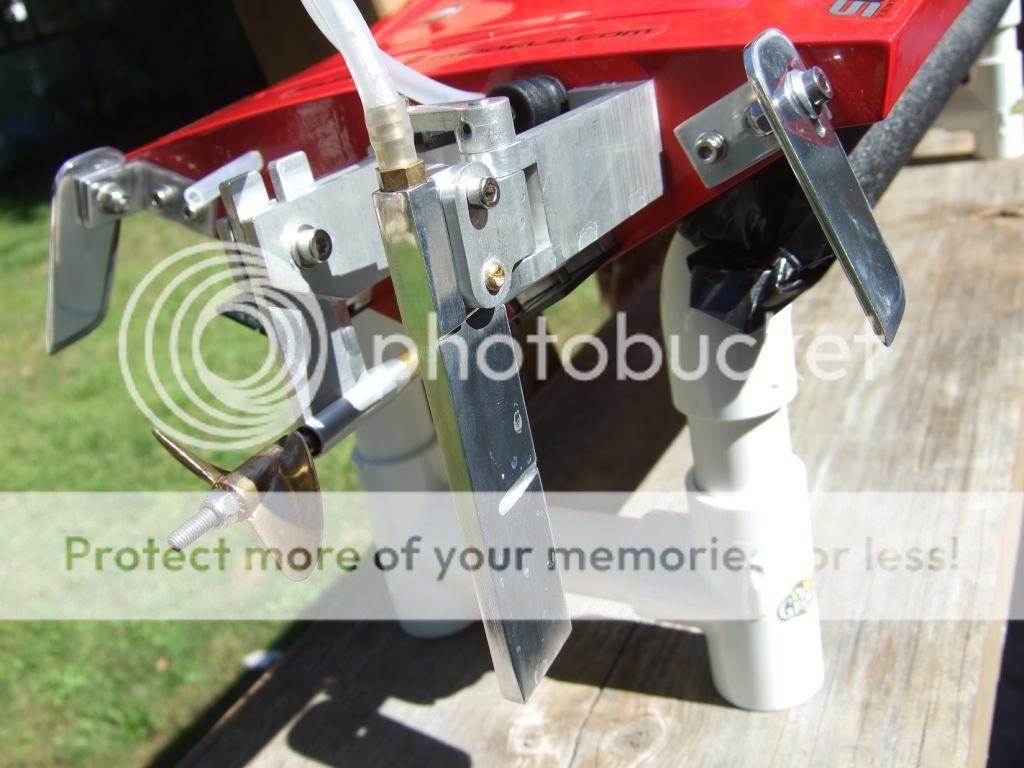

I have had her out for a few runs and I was very impressed with what I assume is the stock setup of the boat. From my limited knowledge it seemed like the boat was stable without being too wet. The second run I sharpened the rudder and turn fins and also filed the cast flashing off the stock prop. Seemed to pick up a bunch more speed when I did this. Ran it a few times with that setup.

The boat has been running well. Everything runs cool and seems very fast for out of the box spec. Looking forward to beefing her up but just want a reliable build I can put a lot of run time into.

I bought this used as a package off eBay. Came with two Grim Racer 2s 5000mAh 40C lipos, an Onyx 245 charger, and a handy ElectriFly PowerMatch.

So far she has been running well. The flex shaft was very dry and somewhat rusty when I got the boat but I cleaned it up well and treated it to a grease bath, most of the friction was pretty much eliminated right away.

I love the Onyx for the dual charge but it is missing a storage charge mode which is kind of inconvenient.

The PowerMatch has been has been great. So far I pretty much just use it to check voltages and power levels which helps me determine run times and what capacity to store the batteries at.

I have had her out for a few runs and I was very impressed with what I assume is the stock setup of the boat. From my limited knowledge it seemed like the boat was stable without being too wet. The second run I sharpened the rudder and turn fins and also filed the cast flashing off the stock prop. Seemed to pick up a bunch more speed when I did this. Ran it a few times with that setup.

The boat has been running well. Everything runs cool and seems very fast for out of the box spec. Looking forward to beefing her up but just want a reliable build I can put a lot of run time into.

Comment