So, I've been running ROAR motors in a few different models for some time now. Recognizing that we cannot use a traditional water cooling jacket because the motor can is open, we are currently relegated to using a coil, a silicone jacket, a heat sink or one of the newer liquid cooling covers which are showing up on RC cars.

In my experience, the silicone jacket doesn't help much. The standard coil is another option, but doesn't have a great effect since there's so little surface area touching the can. Water cooled motor mounts help a fair bit, but still leaves something to desire.

Here's the idea: What if we were able to find somewhat flexible square copper tubing that we could use to create an improved coil that has more contact area with the can?

I haven't tried to source smaller sized square copper tubing, but it is something to consider for those who run these motors.

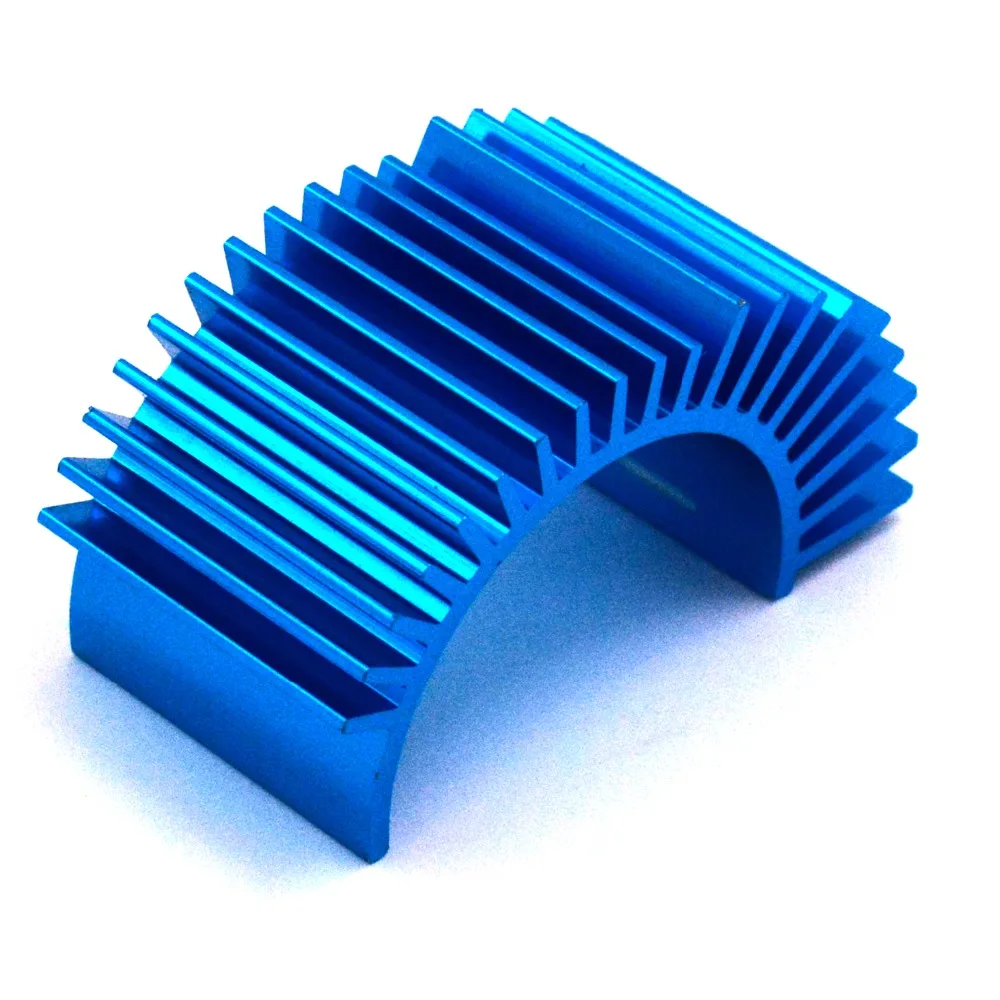

In my boats running the ROAR power plant, I have used the combination of a water cooled motor mount and a heat sink which sits snug against the can. Does anyone have any better ideas?

In my experience, the silicone jacket doesn't help much. The standard coil is another option, but doesn't have a great effect since there's so little surface area touching the can. Water cooled motor mounts help a fair bit, but still leaves something to desire.

Here's the idea: What if we were able to find somewhat flexible square copper tubing that we could use to create an improved coil that has more contact area with the can?

I haven't tried to source smaller sized square copper tubing, but it is something to consider for those who run these motors.

In my boats running the ROAR power plant, I have used the combination of a water cooled motor mount and a heat sink which sits snug against the can. Does anyone have any better ideas?

< Please note that this is an example pic. In no way am I using a 8.5T motor, just to be clear. I just grabbed a pic from the web to demonstrate the point.

< Please note that this is an example pic. In no way am I using a 8.5T motor, just to be clear. I just grabbed a pic from the web to demonstrate the point.

Comment