Okay I was close to bumping an old thread for something I read a few times earlier in the discussion really irked me, however I felt it would possibly be a positive thing if some interesting concepts and theories were brought to the table. So I decided to just make a new thread instead. Hopefully it just provides a medium for good healthy debate, and I always enjoy a good discussion on fluid dynamics.

Guys, you dont need to have run several world class boats or been in a certain industry of work and education to draw an accurate conclusion with their boats watercooling setup. Its pretty simple to generally understand how thermal and fluid convention are related when it comes to heat/expelling heat. If were going to play that game, then Id like to mention that I build custom high end computers and all of them have sophisticated custom watercooling setups that I always design. But regardless, the overall perspective of how they work is extremely simple, and our RC boat watercooling setups are..... ridiculously more simple than those.

To believe that having "too much flow" is ludicrous ONLY in the sense that one assumes it somehow doesn't leave enough time for heat transfer to take place. Guys, if water touches a fire, that fire is going to suffer as a result, period. To act as if the fire would somehow be unaffected if the said water was somehow able to pass through it fast enough is silly.

Now, when one of you guys experience what appears to be a drop in cooling performance simultaneously with an improvement in flow, I promise you it is because of a lack or decrease in pressure. For example, when anyone builds a watercooling loop (loop is important here), the key components are the item being cooled/cooler, radiator, pump, and reservoir. Without getting into the purposes of each, the reservoir specifically serves only one purpose (despite some elaborate or large reservoirs, these exist solely for looks or ergonomics) which is to bleed air out and render the entire loop under pressure. Since both RC boat watercooling and PC watercooling dont actually have water flowing in/throughout the heat producer, the expelling of air is absolutely critical for thermal exchange to occur between the surfaces that are hot. Additionally, since our RC boat watercooling setups are NOT a loop and the water outlet is always exposed openly in order for us to see and confirm the flow, they are much much more susceptible to air entering and negatively effecting cooling performance.

Like I have heard from many that I must make sure that I have a pretty consistent application of full or near full throttle throughout the duration of my runs due to the need to make sure their is adequate water cooling the components inside. But thats not adequate water, thats adequate flow. And that rings true entirely.

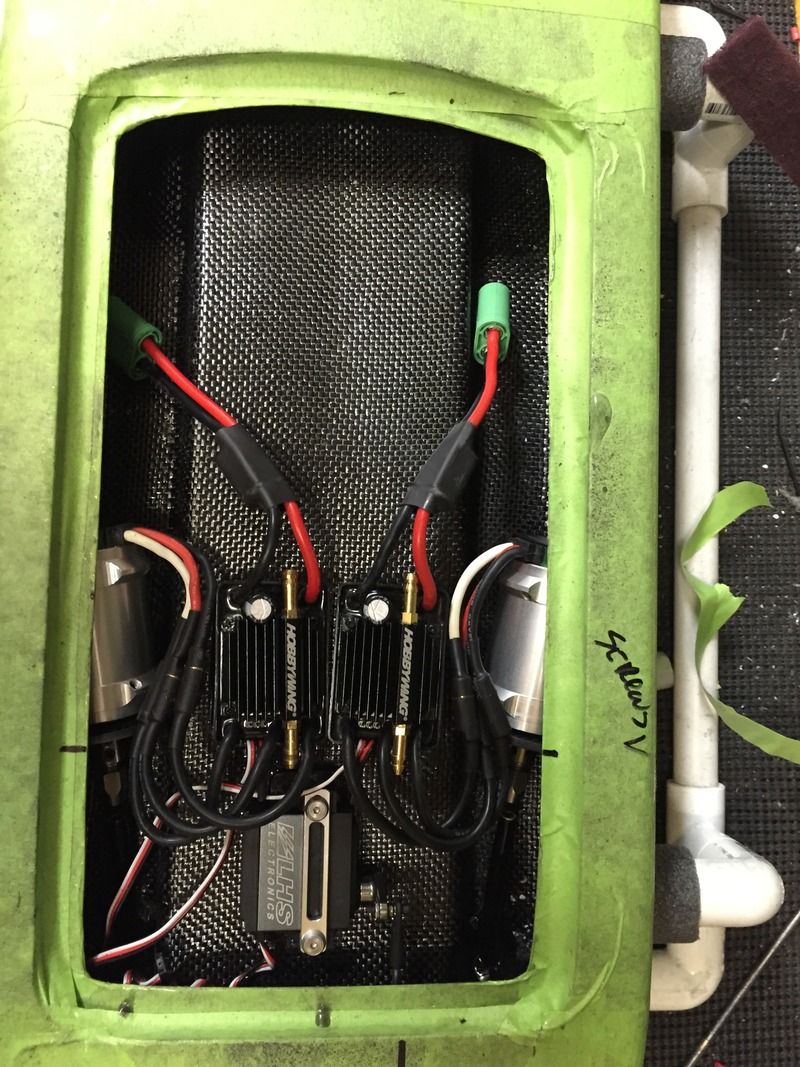

BTW, heres a picture of my personal computer, and another that i just finished for my most recent customer :) if anyone wants or knows someone who works in software, web design, 3D rendering, is a gamer, or basically just needs a high end custom computer, point them my way!

Guys, you dont need to have run several world class boats or been in a certain industry of work and education to draw an accurate conclusion with their boats watercooling setup. Its pretty simple to generally understand how thermal and fluid convention are related when it comes to heat/expelling heat. If were going to play that game, then Id like to mention that I build custom high end computers and all of them have sophisticated custom watercooling setups that I always design. But regardless, the overall perspective of how they work is extremely simple, and our RC boat watercooling setups are..... ridiculously more simple than those.

To believe that having "too much flow" is ludicrous ONLY in the sense that one assumes it somehow doesn't leave enough time for heat transfer to take place. Guys, if water touches a fire, that fire is going to suffer as a result, period. To act as if the fire would somehow be unaffected if the said water was somehow able to pass through it fast enough is silly.

Now, when one of you guys experience what appears to be a drop in cooling performance simultaneously with an improvement in flow, I promise you it is because of a lack or decrease in pressure. For example, when anyone builds a watercooling loop (loop is important here), the key components are the item being cooled/cooler, radiator, pump, and reservoir. Without getting into the purposes of each, the reservoir specifically serves only one purpose (despite some elaborate or large reservoirs, these exist solely for looks or ergonomics) which is to bleed air out and render the entire loop under pressure. Since both RC boat watercooling and PC watercooling dont actually have water flowing in/throughout the heat producer, the expelling of air is absolutely critical for thermal exchange to occur between the surfaces that are hot. Additionally, since our RC boat watercooling setups are NOT a loop and the water outlet is always exposed openly in order for us to see and confirm the flow, they are much much more susceptible to air entering and negatively effecting cooling performance.

Like I have heard from many that I must make sure that I have a pretty consistent application of full or near full throttle throughout the duration of my runs due to the need to make sure their is adequate water cooling the components inside. But thats not adequate water, thats adequate flow. And that rings true entirely.

BTW, heres a picture of my personal computer, and another that i just finished for my most recent customer :) if anyone wants or knows someone who works in software, web design, 3D rendering, is a gamer, or basically just needs a high end custom computer, point them my way!

Comment