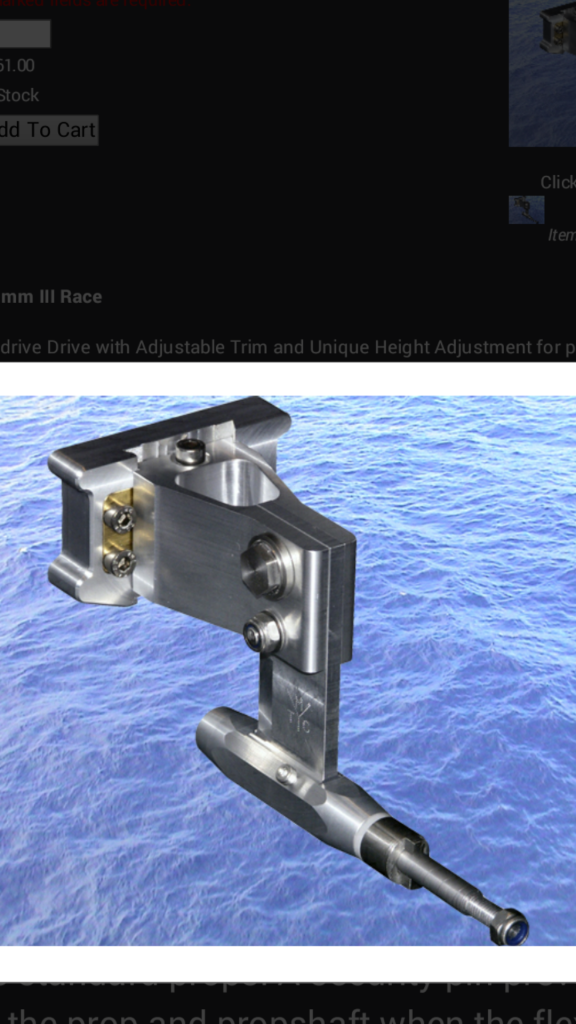

I need your help....in my Neverending quest to make my little 32" cat go faster, I've come to a roadblock of sorts. The strut adjustment on it is quite....unaccurate and hard to repeat. So I want to make a much better strut mount. My mill is a manual on and isn't as accurate as I'd like it to be and I know I can't make it as nice as a cnc mill can. I'm willing to pay you btw. Maybe someone could do a better job than me on a manual mill..I ordered some cutting bits to try it myself.... Here's what I'm looking for...something like this (this one is for a big gas boat, otherwise I'd just buy it and be done lol)

I'm also open to ideas and suggestions. ..please no negativity. ...or telling me I can adjust it just fine with what I have...I know I can, I want a more repeatable system for testing.

I want to continue to use the bottom strut part...just need to make the two sliding parts...

I'm also open to ideas and suggestions. ..please no negativity. ...or telling me I can adjust it just fine with what I have...I know I can, I want a more repeatable system for testing.

I want to continue to use the bottom strut part...just need to make the two sliding parts...

His stuff is very good quality, alot better than the other custom manufacturer I dealt with recently

His stuff is very good quality, alot better than the other custom manufacturer I dealt with recently  .... Dave's turn around time is very reasonable too... DJ

.... Dave's turn around time is very reasonable too... DJ

Comment