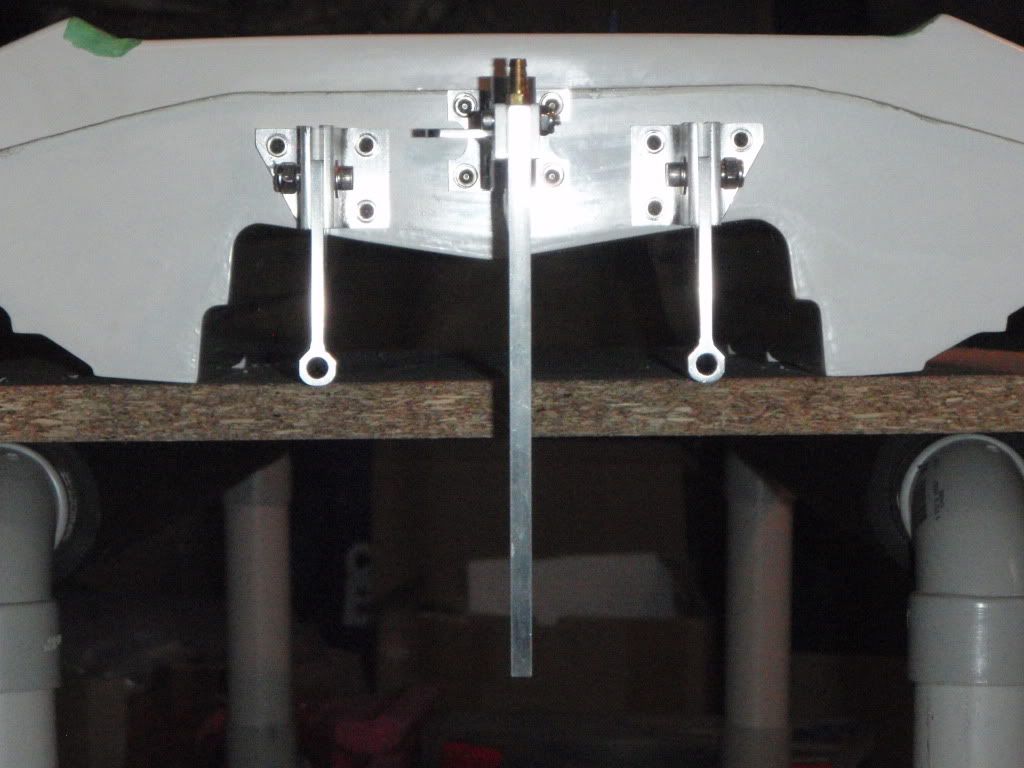

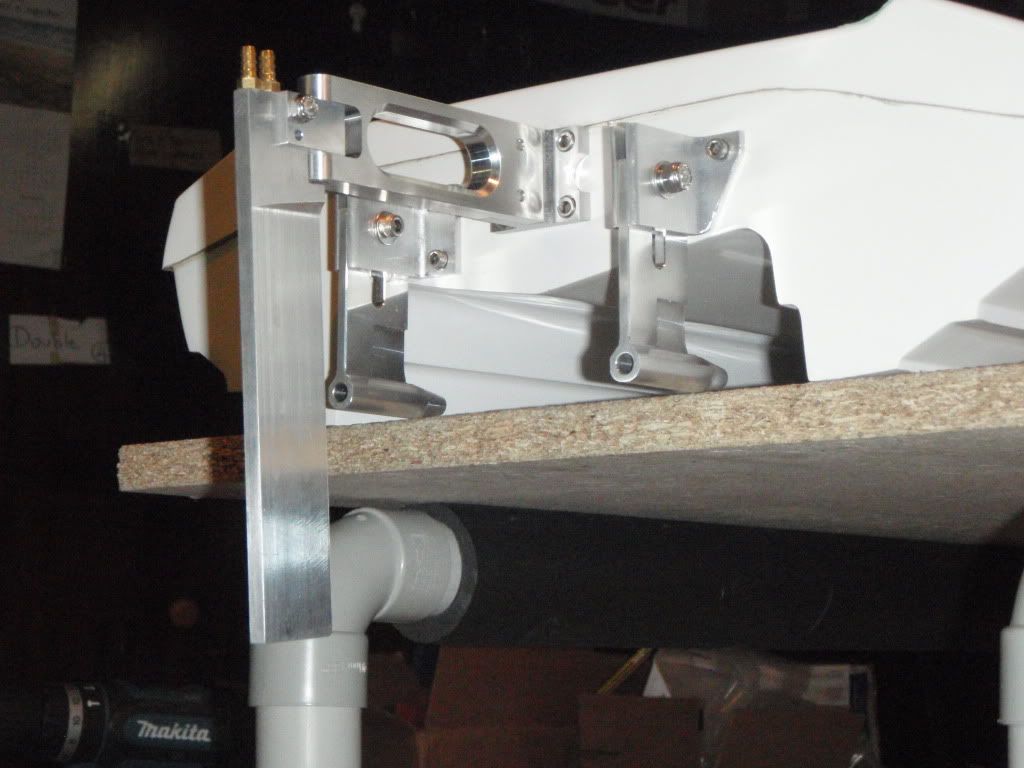

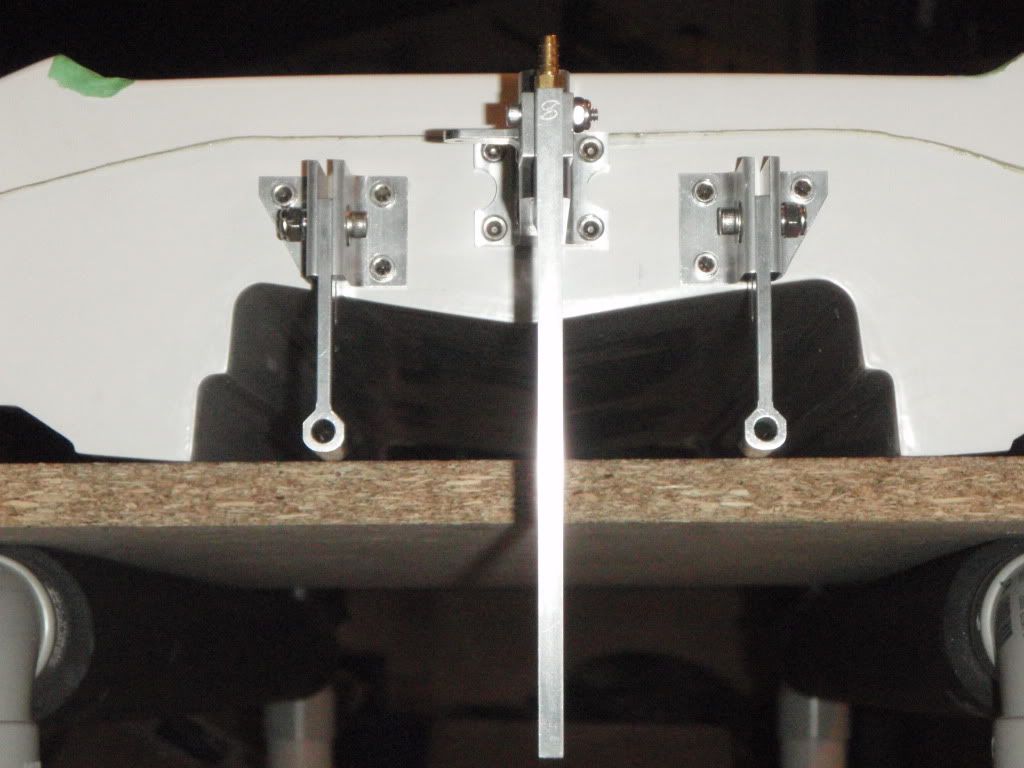

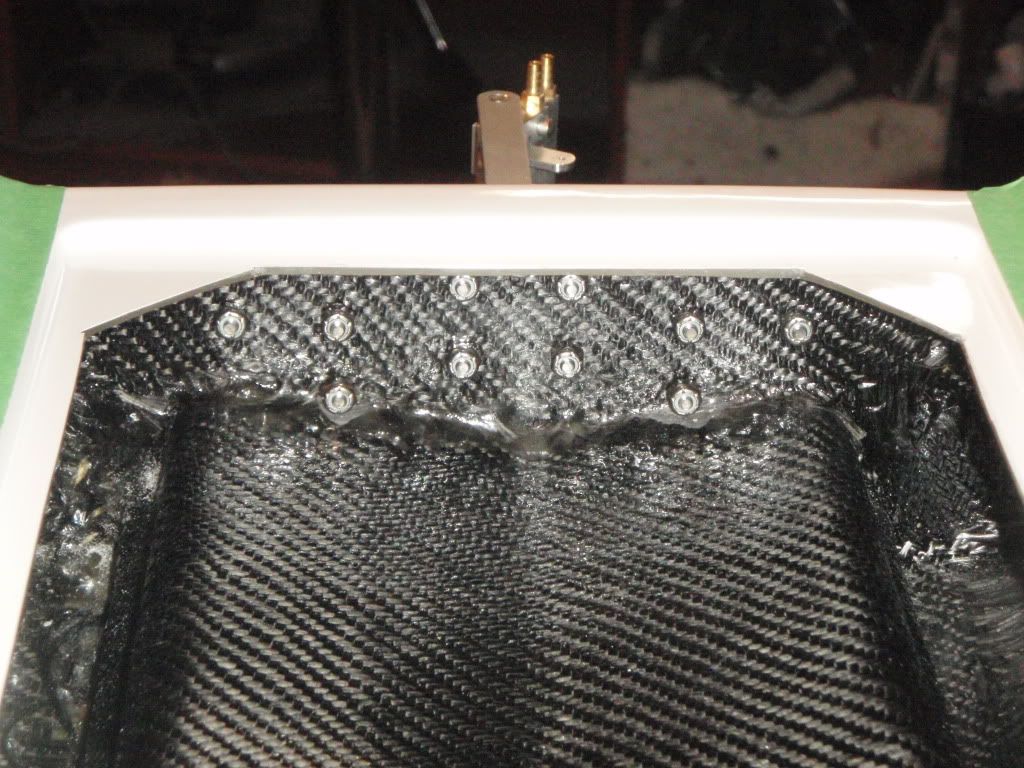

After playing around with a few different hardware mounting options, I found that the transom on the 42" SC I have is not symmetrical, I mean the small v in the tunnel is not a true center between the sponsons it's peak is about 4-5mm off to the left, so after a quick phone call to a wiseman I found the true center and worked off that. Another small issue I've come across is that the strut heights I have are a tad short, I've drilled them out as much as I think is safe but they still leave my mounting options limited. I have however come up with two options but I have come to a stand still, I'm a little undecided on which way to go I've attached a few pics and will try to explain what I'm thinking.

Option A

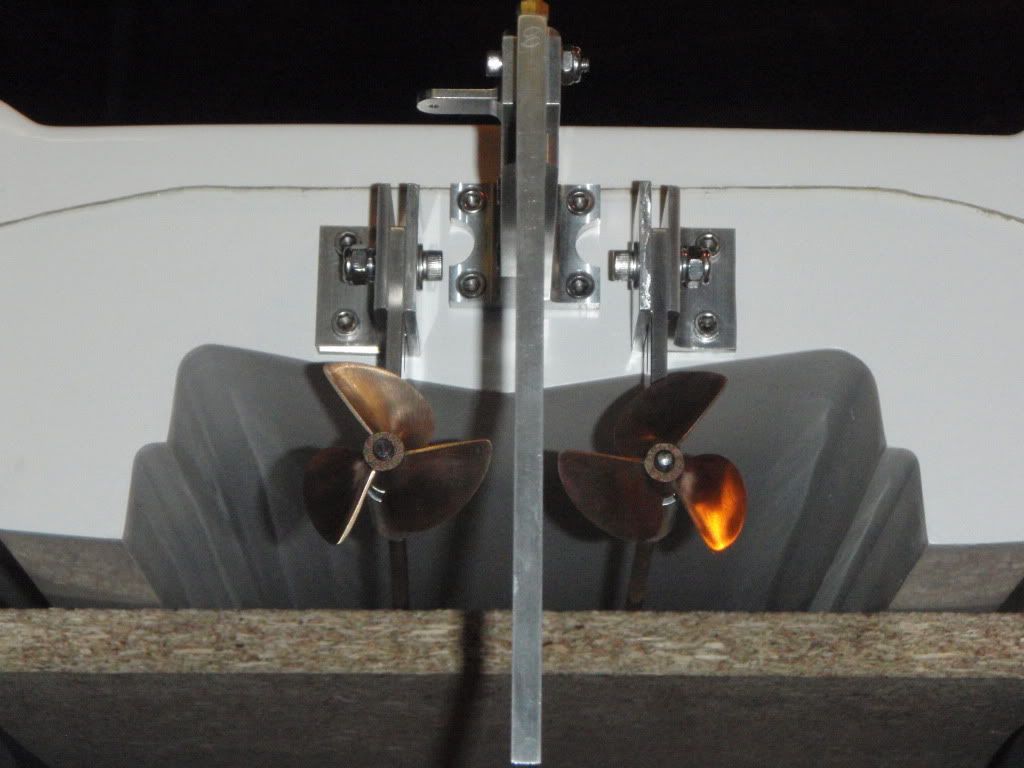

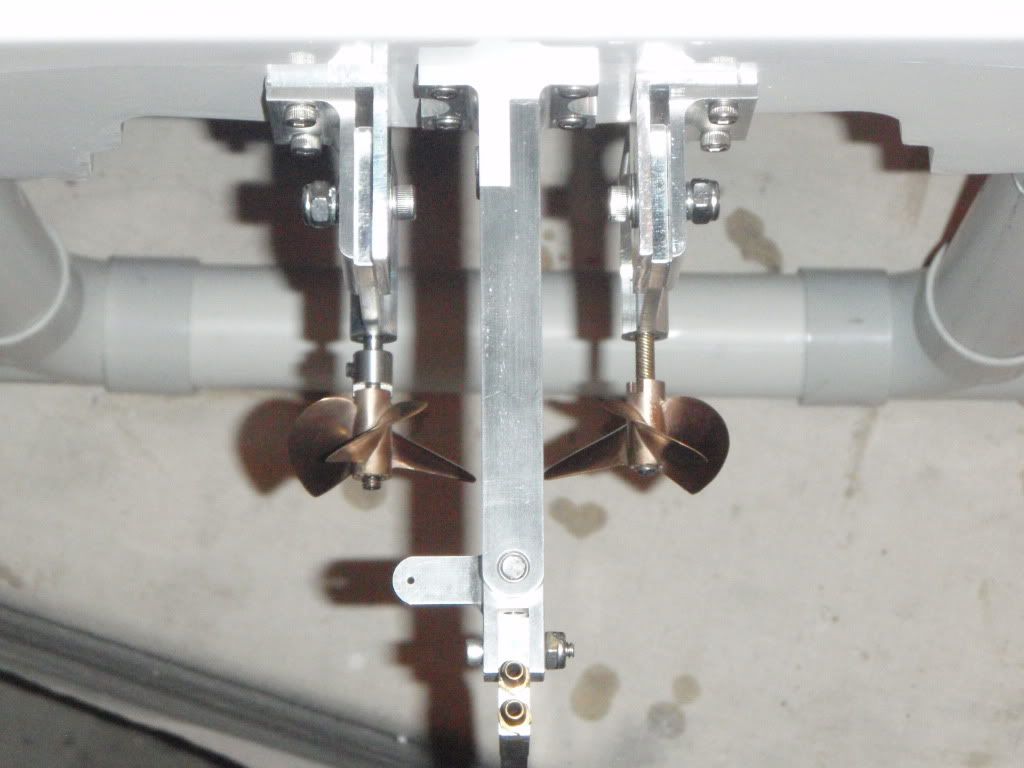

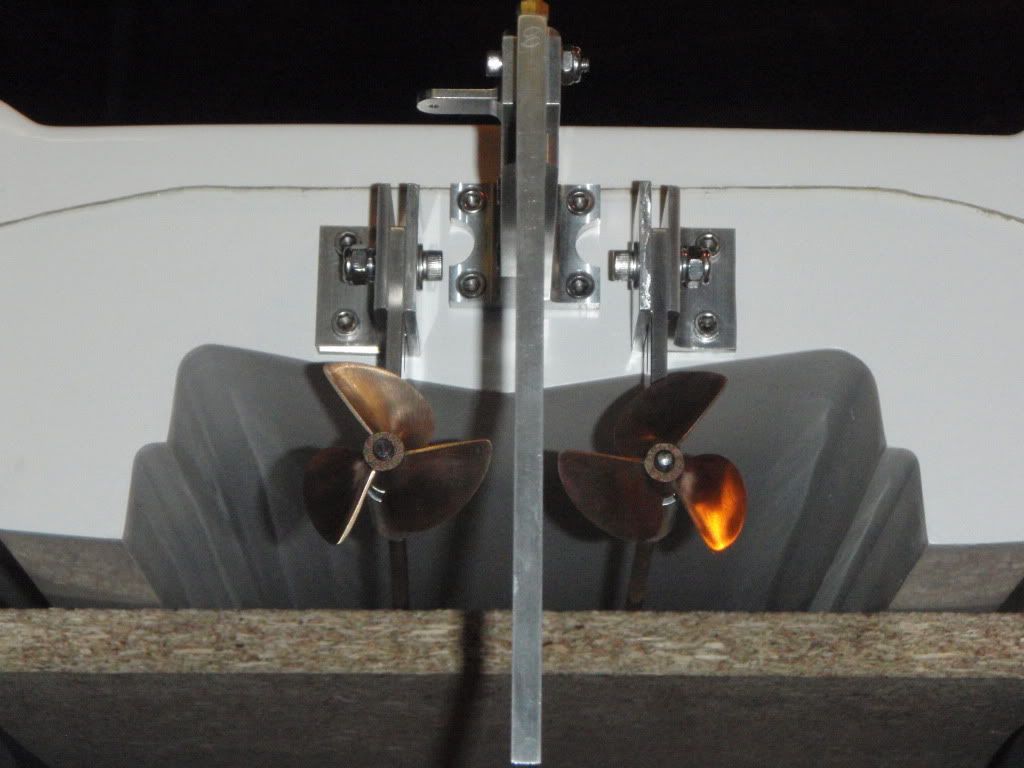

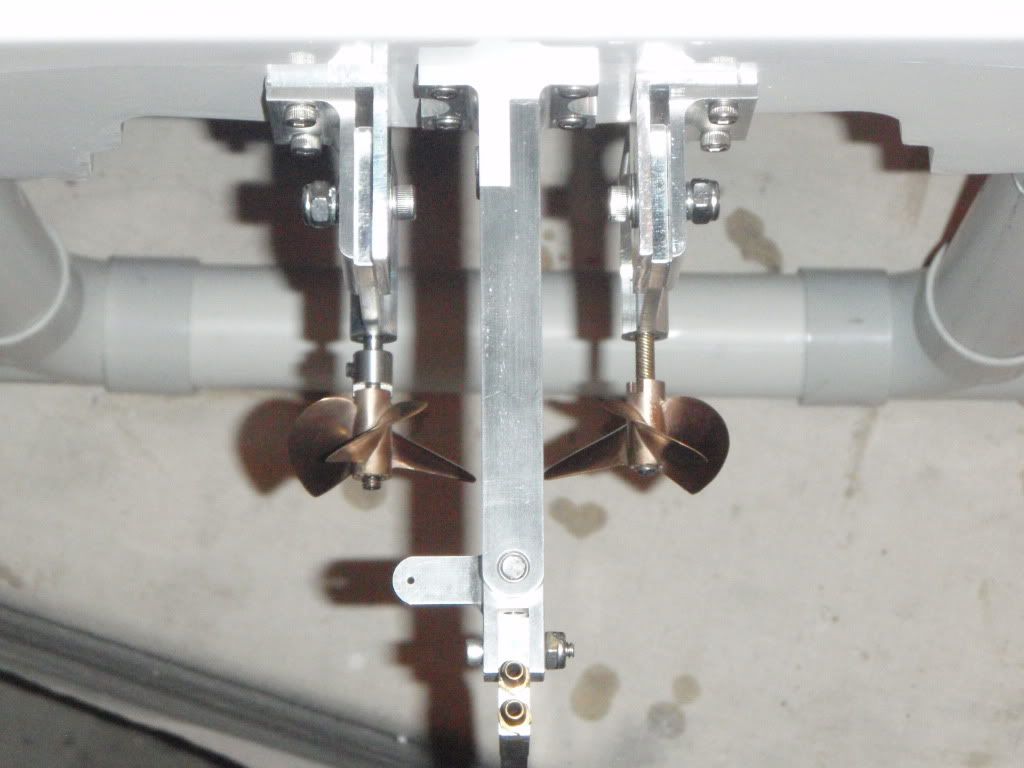

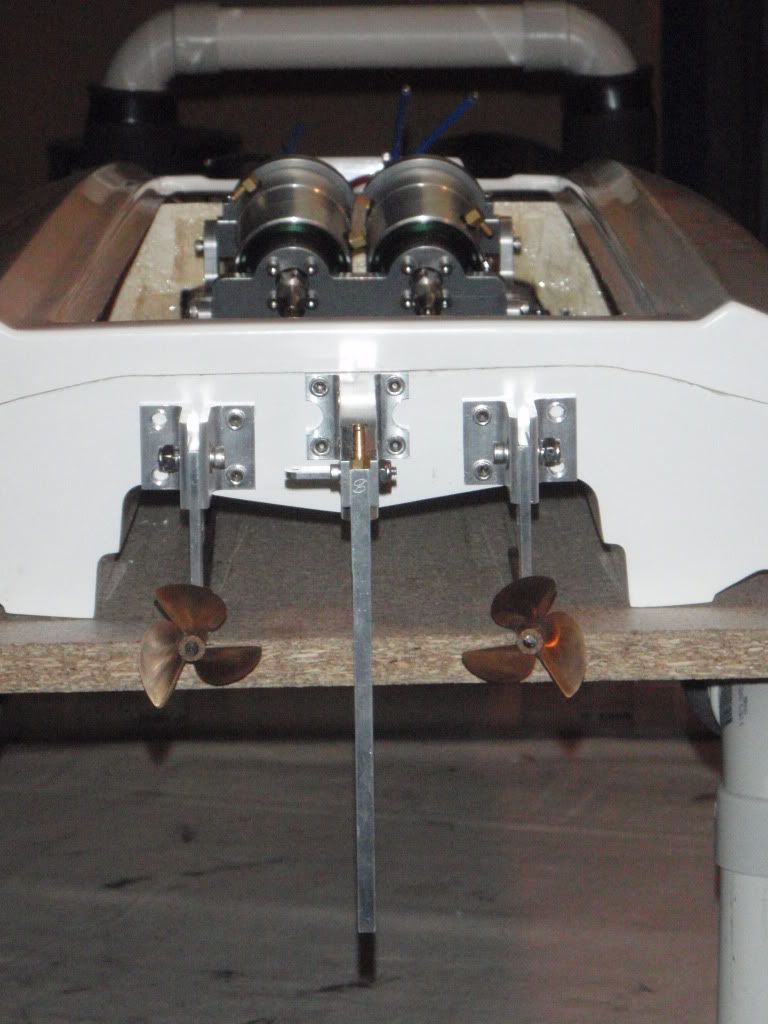

I measured the distance between the center of the couplers with the motors fitted in the twin motor mount, it was 64.5mm. Thinking that it would be easier for me to have one gradual sweeping bend in the stuffing tube, I figured I'd see how the struts would go at the same distance (center of the flex shaft in the strut would be 64.5mm). The biggest props I think I'd use are x450/3 l&r, thus leaving approx. 12-15mm distance between the prop tips. Mounting the struts like this made me have to come up with a more secure mounting bracket as I can only use one side so I made up the opposing side with some 50x50x3mm angle aluminum and drilled a few holes to suit the other side. With the strut level with the bottom of the sponsons, the bottom screw in the mounting bracket only just has enough clearance to put the nut on inside the hull above the floor of the tunnel and the inside of the transom. After fitting the hardware the props looked a bit close, they have approx 15mm gap between tips but I'm a little worried about propwash and how well they will work. Please take a look at the pic's and offer me some advice.

Option B

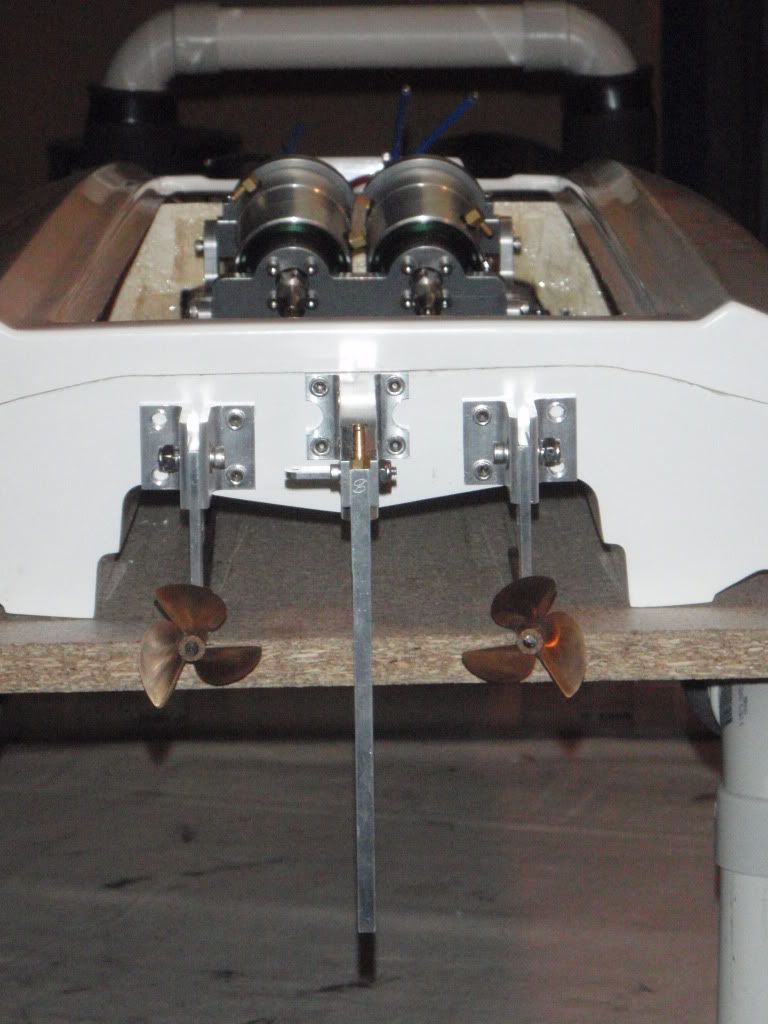

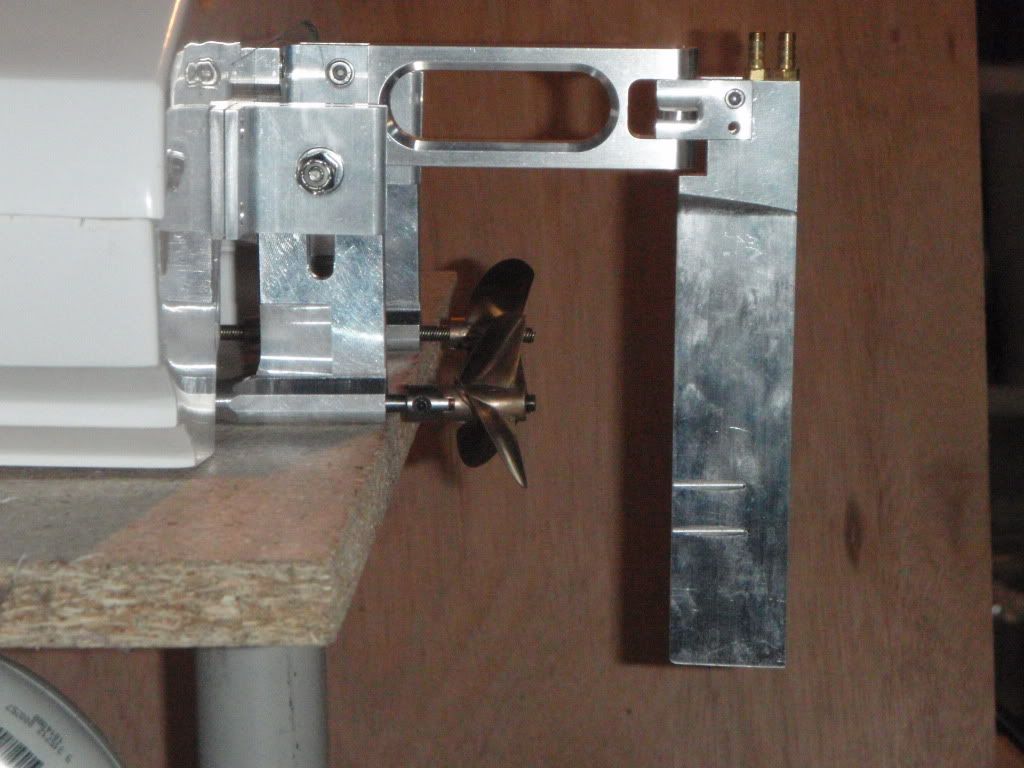

After looking closely at option A, I thought I'd better find an alternative. The easiest being that I remove the inside brackets that I made, move the strut over and use the original bracket using the drilled holes for the inside strut mount. This has eased my issue with propwash but has raised a few others, the bottom hole on the outside strut mount will not be able to be drilled, it'd almost be inline with the tunnel floor so I would simply remove the bottom corner (including the bolt hole) of the mount and just drill and bolt the top hole. Doing this would also remove the overhang of the bottom corner of the mount that could cause tunnel air issues in the future. The other issue that I'd have if I go this way is bending the stuffing tube, it'd be in a bit of an s-bend, I haven't done one b4 and would be more confident with a single bend. I'm sure I'll soon learn.

Which of the above ways should I choose???????????????????????????????????????????? ????????????????????????

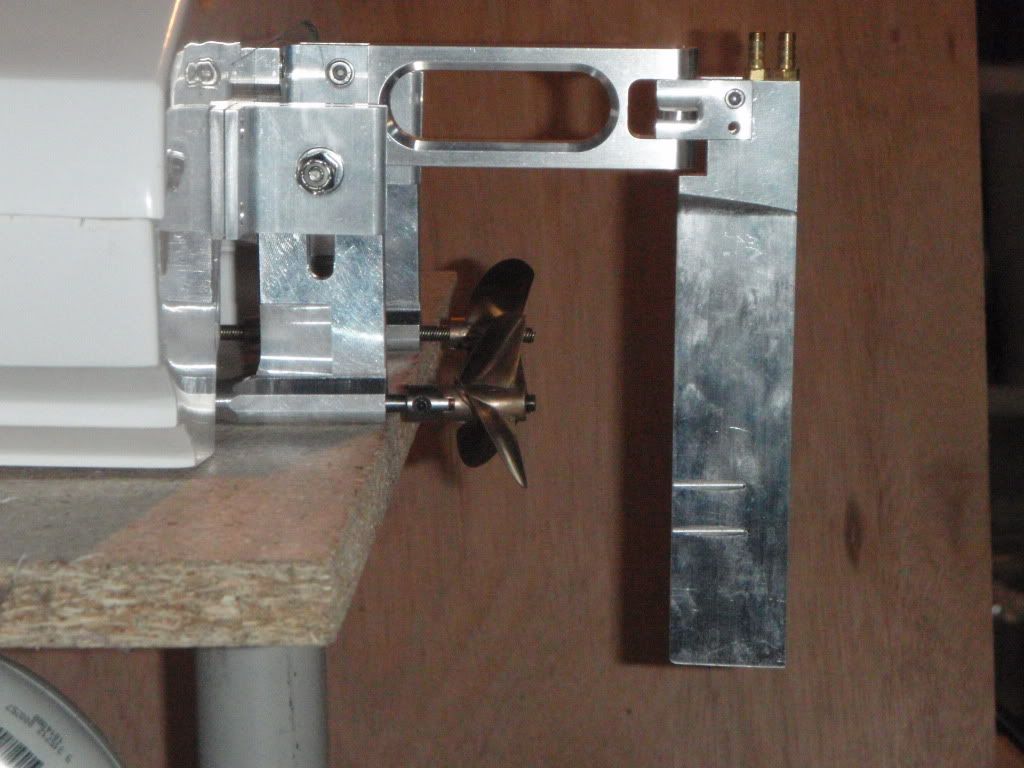

and is this rudder set back too far?????????????

Option A

I measured the distance between the center of the couplers with the motors fitted in the twin motor mount, it was 64.5mm. Thinking that it would be easier for me to have one gradual sweeping bend in the stuffing tube, I figured I'd see how the struts would go at the same distance (center of the flex shaft in the strut would be 64.5mm). The biggest props I think I'd use are x450/3 l&r, thus leaving approx. 12-15mm distance between the prop tips. Mounting the struts like this made me have to come up with a more secure mounting bracket as I can only use one side so I made up the opposing side with some 50x50x3mm angle aluminum and drilled a few holes to suit the other side. With the strut level with the bottom of the sponsons, the bottom screw in the mounting bracket only just has enough clearance to put the nut on inside the hull above the floor of the tunnel and the inside of the transom. After fitting the hardware the props looked a bit close, they have approx 15mm gap between tips but I'm a little worried about propwash and how well they will work. Please take a look at the pic's and offer me some advice.

Option B

After looking closely at option A, I thought I'd better find an alternative. The easiest being that I remove the inside brackets that I made, move the strut over and use the original bracket using the drilled holes for the inside strut mount. This has eased my issue with propwash but has raised a few others, the bottom hole on the outside strut mount will not be able to be drilled, it'd almost be inline with the tunnel floor so I would simply remove the bottom corner (including the bolt hole) of the mount and just drill and bolt the top hole. Doing this would also remove the overhang of the bottom corner of the mount that could cause tunnel air issues in the future. The other issue that I'd have if I go this way is bending the stuffing tube, it'd be in a bit of an s-bend, I haven't done one b4 and would be more confident with a single bend. I'm sure I'll soon learn.

Which of the above ways should I choose???????????????????????????????????????????? ????????????????????????

and is this rudder set back too far?????????????

Comment