I still can't believe I have to ask for some help/advice on soldering, but it has been a while....

OK, I got the job done, and I got it done right but wow did I ever struggle the other night soldering my 10awg cable to 5.5mm bullitts. Seemed like the heat just would not get in to the wire. The wire did not want to wick the solder all that well. I have good solder and I am using a 400w soldering gun. No problems there... The only thing I can think of is, I was using a metal plate that was on a old towel to solder. I was laying the wire directly on to the metal plate and trying to tin it. I am thinking my metal plate was soaking all the heat out of my wire and that is why I was having problems. I looked at some youtube videos and it looks like most of you are using a piece of plywood to solder on, and also with 8-10awg wire you have to tin both sides of the wire??? is this correct?

Last thing, I went ahead and ordered one of these helping hands things. Seems like a good idea, but I don't know. http://cgi.ebay.com/ws/eBayISAPI.dll...=STRK:MEWNX:IT

It's been a few years since I have soldered anything really. Back when I used to solder I had a glass table I soldered directly on. It had sides so I didn't need anything to hold conns or wire. I could just push them in to the sides to hold and the glass never skipped a beat with the heat. (Just looked at more video's and everyone is using wood to solder on. I think this may have been my problem)

Thoughts? Advice? Thanks.

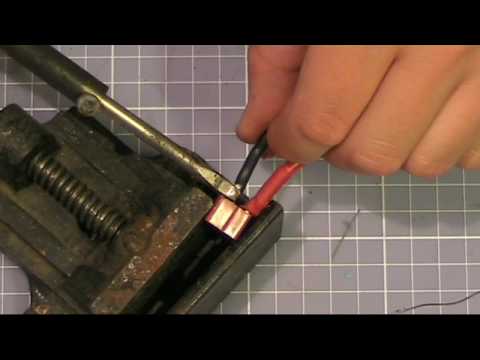

Finished product below.... Wish me luck at the pond later... First time in almost three years...

OK, I got the job done, and I got it done right but wow did I ever struggle the other night soldering my 10awg cable to 5.5mm bullitts. Seemed like the heat just would not get in to the wire. The wire did not want to wick the solder all that well. I have good solder and I am using a 400w soldering gun. No problems there... The only thing I can think of is, I was using a metal plate that was on a old towel to solder. I was laying the wire directly on to the metal plate and trying to tin it. I am thinking my metal plate was soaking all the heat out of my wire and that is why I was having problems. I looked at some youtube videos and it looks like most of you are using a piece of plywood to solder on, and also with 8-10awg wire you have to tin both sides of the wire??? is this correct?

Last thing, I went ahead and ordered one of these helping hands things. Seems like a good idea, but I don't know. http://cgi.ebay.com/ws/eBayISAPI.dll...=STRK:MEWNX:IT

It's been a few years since I have soldered anything really. Back when I used to solder I had a glass table I soldered directly on. It had sides so I didn't need anything to hold conns or wire. I could just push them in to the sides to hold and the glass never skipped a beat with the heat. (Just looked at more video's and everyone is using wood to solder on. I think this may have been my problem)

Thoughts? Advice? Thanks.

Finished product below.... Wish me luck at the pond later... First time in almost three years...

Comment