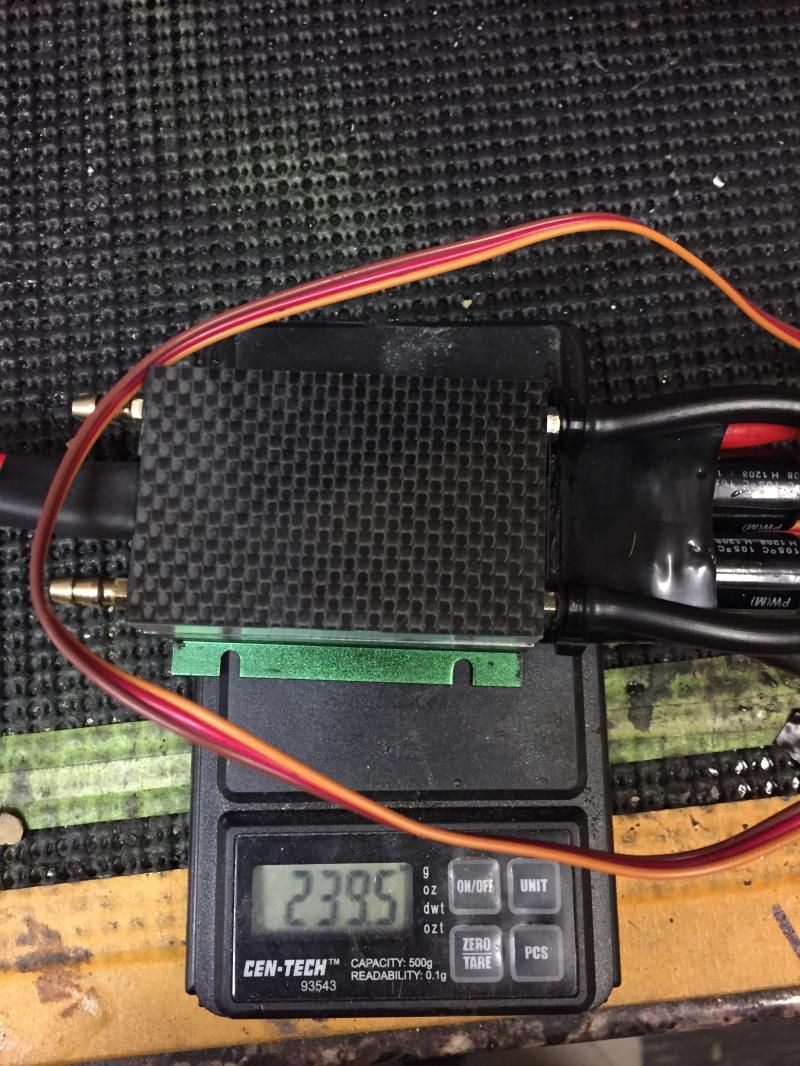

I think it looks really good, but also rather heavy. If I were trying to do a similar thing mine would not look anywhere near as neat but it would be lighter, that is not knocking what you have done, we are just after different things from our boats.

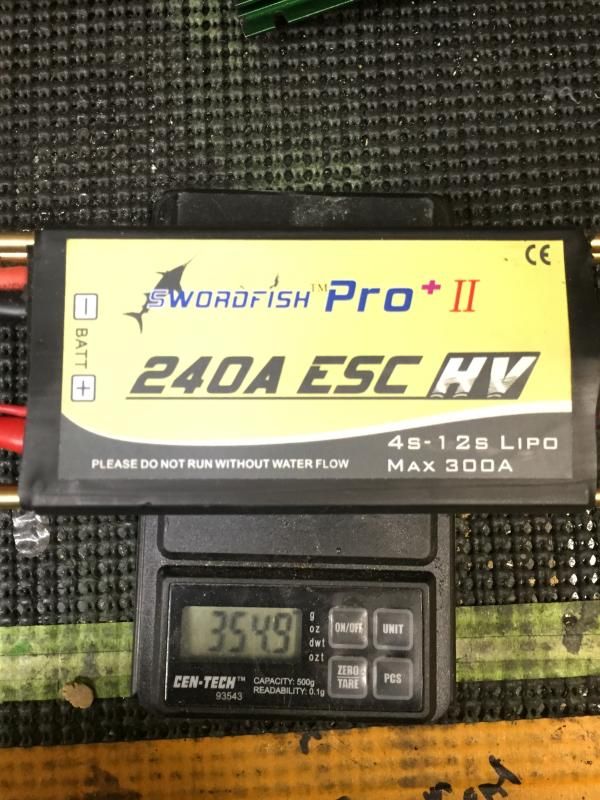

Aesthetically the 3 wire end with the water fittings screwed through the carbon plate looks much better to me than the 2 wire end with exposed blocks.

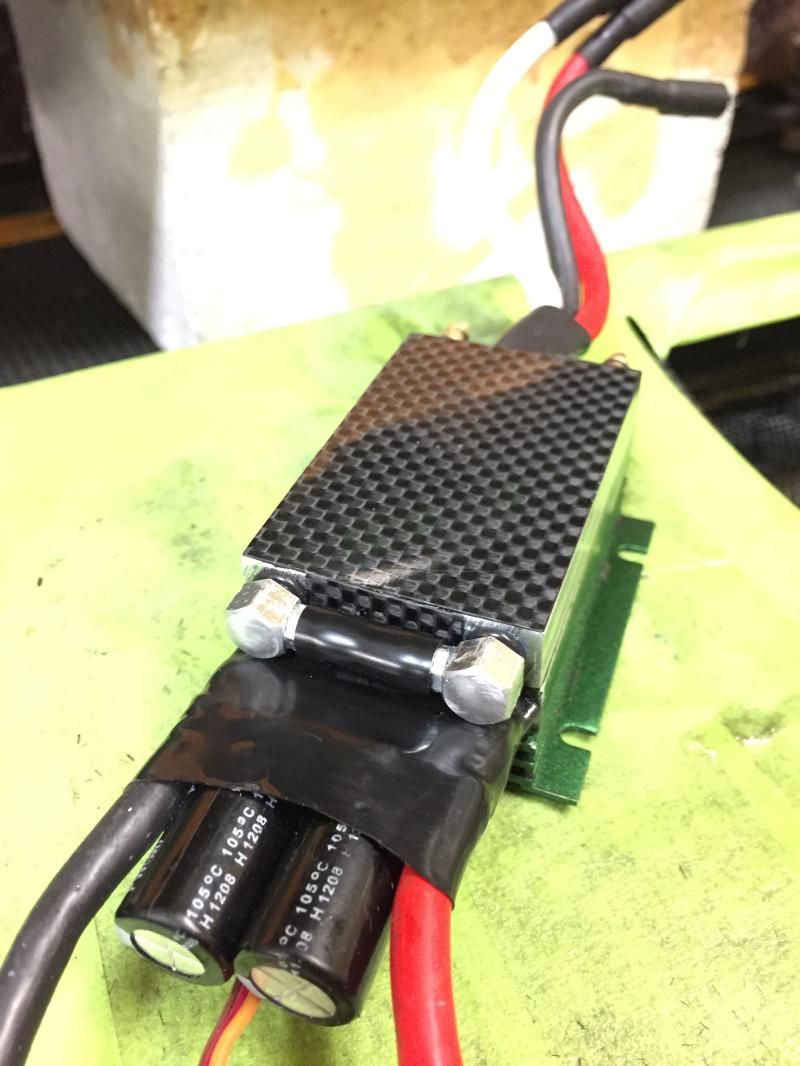

How do you have the cooling blocks attached? If you added carbon plates to the sides you could hold them in place well enough to use regular heat sink paste which is a much better conductor than thermally conductive epoxy and massively better than potting compounds.

Aesthetically the 3 wire end with the water fittings screwed through the carbon plate looks much better to me than the 2 wire end with exposed blocks.

How do you have the cooling blocks attached? If you added carbon plates to the sides you could hold them in place well enough to use regular heat sink paste which is a much better conductor than thermally conductive epoxy and massively better than potting compounds.

Nortavlag Bulc

Nortavlag Bulc

Comment