Hey Mic, what is divinicell 3/4? and G10 ?

36 inch rigger slow

Collapse

X

-

-

I will try to remember to take some photos tomorrow when it is light. My sponsons are a glass top bottom and outside molding with a carbon sheet inside face, they are empty.

I cant recall if it has one in there now or a cheap Suppo, but when I had the cash I was a big fan of ESCs with datalogging, like the Castle Creations Ice range, no bigger than any other and give you a lot of info to help with setup.

If it is perfect in all ways but the GPS, just stop running the GPS and be happy!

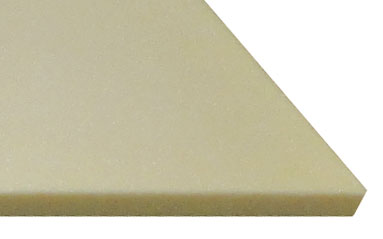

Divinicell is a closed cell extruded PVC foam available in several densities but is generally much heavier and stronger than expanded or extruded polystyrene foams, 3/4" is just the width of the foam he used for his sponsons. G10 is an epoxyglass with a USA certification for PCBs, it's very consistent, fairly strong and fairly easy to get hold of.Paul Upton-Taylor, Greased Weasel Racing.Comment

-

Divinnycell is a dense somewhat structural foam that makes sponsons a bit more ridged and better to fasten boom tube supports.

Divinycell Foam Pvc Divinycell is a closed cell medium to high density foam which has high compression strength, durability, and excellent fire resistance.

Divinycell Foam Pvc Divinycell is a closed cell medium to high density foam which has high compression strength, durability, and excellent fire resistance.

G-10 is an epoxy glass composite I skin sponsons and use for running surfaces that is much cheaper than carbon fiber.

Mic Halbrehder

IMPBA 8656

NAMBA 1414Comment

-

Mic, I just noticed your point about rudder angle, I missed it back when I read your reply. Could you please expand on your comment it might explain a problem I have.

I fitted bigger sponsons, the set up weighs 7.6 pounds so I thought looking at the ML380build of SammyHal (my first wood build)as he got great speed out of a heavy set up with bigger sponsons, he also is running quite a lot of tub clearance to the water.

so when I made the bigger sponsons I also raised the tub,I also made a turn fin like the ML 380 has and looked at his CG and copied his battery and esc and motor and turn fin placement so now I have mire speed.but it turns way to sharp.

so I tried no turn fin as the sponsons dip in on a turn and I blamed my home made turn fin but this only helped slightly,the rigger still turns way to hard both ways.ss then tried higher AOT on the sponsons,thinking they are to low at the front at 3.5 degrees.so it?s now 5 degrees and its still no good ,I now realised I raised the tub height at the sponsons but not the rear shoes thus I think it has added forward angle at the bottom of the rudder.

Could this cause the sponsons to dip in ?

It will even bury the inside sponson under the water and then turn in its own length.Comment

-

Angling the bottom of the rudder towards the bow will cause the stern to squat, that?s not the problem although the rudder hinge should usually be set perpendicular to the water surface.

- Where is the CG relative to the center of the turn fin?

- Is the tub offset to one side?

- On which side of the transom is the rudder mounted?

- How much movement is there at the back of the rudder, full left to full right?

- At what speeds does it turn too sharply, full or part throttle?

- Why is the OP trying to turn hard left?

- Exactly what rudder servo is being used?

- What is “mire speed”?

Actually, without some photos it will be tough to diagnose the OP?s issue.

- side view of entire rigger sitting on a table with CG position marked

- transom rear view showing rudder and strut

- top view of entire boat

- rear view of right sponson showing fin

.ERROR 403 - This is not the page you are looking for

Comment

-

Fluid (Jay T) has summed it up pretty well. In general I try to keep the tub and strut parallel to the water surface and rudder perpendicular. AS stated photos and detailed info on motor esc and batts help the diagnosis.

Mic

Mic Halbrehder

IMPBA 8656

NAMBA 1414Comment

-

Thank you both Fluid and Mic for your reply and insight,

I don't know yet how to post photos to this forum but I try to sort it out.

This rigger was very twitchy in its handling until I moved the turn fin forward a few inches and limited the servo travel to about 1/8 inch either way off center.

Prior to doing these two things, It would be going along at full speed and it would literally spin out at full speed at the slightest movement of the steering, seamingly on its own.

Once I done these 2 things it at least was able to get up to full speed and go straight but I am too scared now to give it a turn at full speed to see what it does so I have been slowing down to turn at this lower speed lets say 35 mph The sponson seams to dip in if turning to the right it can dip in that hard it spins out in its own length and the sponson can go completely under the water.

I tried it with the fin off completely and it is the same.Since my reply to mick I looked at the rudder angle and it is at 90 degrees to the water surface.

The photos will show the 5000 mah 50 c HRB 6S lipo at the front of the tub then the 200 amp ZTW Seal esc behind the lipo this ESC touches the front of the TP 4060 6D 1650KV motor right at this point is the COG, the COG is at the rear tip of the sponson. the steering servo and the radio receiver are nearer to the back of the rigger.

The rigger weighs 7.6 pounds ready to run.

I'm running a sharpened and balanced ABC 1717. I could not buy a 1816 in Australia at the moment but at least its better than the Octura M447 and the X452

The part of the sponson that touches the water at full speed is about 11/4 inches forward of the rear end of the lipo and about 6 inches forward of the COG.or 6 inches forward from the very back of the sponson.

I have tried the turn fin in 2 places firstly,wrapped around the rear sponson boom tube, this is puts the rear tip of the fin 11/4 inches forward of the COG this spot I thought would perfect compared to Riggers I have had in the past but it was not.

The second position was forward of this position so the leading edge of the fin was exactly at the trailing edge of the rear riding surface of the sponson so basically there was no air gap from the rear of the sponson step up, to the turn fin.

This position I copied from the ML RSX 380 on this forum(Sam Hallstom, my first wood build)Also this is where I got the size of the sponson running surface from and the layout of the LIPO ESC and Motor because its a similar size to my rigger with not to different motor and he is actually even heavier than my rigger.

I checked the ML RSX 380 on ML's web site and there is a side on shot showing like a see thru image of the battery and esc and motor in relation to the sponson tips etc.

This is not where I started of course, I started trying to build a bit bigger carbon fibre version of the KEPS rigger to suit the high powered very long TP motor I accidently purchased not knowing that 40 60 meant something different than 40 mm diameter and 60 mm long for some reason it means 40 mm X 92 mm after building it this way and it did not have any speed I went looking for possible reasons why, looking at the ML RX 380 and it having such big sponson and still handling and going fast I thought my sponsons were just to small for the weight.

So now I have more speed, not (MIRE) SPEED sorry Fluid it was just a typo. but the cornering is weird I am no expert and love playing with things even if I give up on this home made rigger and bought the ML RX 380 I would still build it and mould it so I could save the weight and have carbon fibre.

I would never do this as a business, its all to hard,and I am not good enough at making things look pretty but making these things go fast and not leak is well. an addiction now I am hooked.

Plus I live on the water on Lake Macquarie her in Australia so running them is easy but it comes with the salt water associated damage and cost when things go wrong.

Its says I can post attachments BELOW but I hover the mouse over where it says this and nothing happens, could someone instruct me on how to attach the photos.Comment

-

Yes, we really need photos. Basically you need to go to Go Advanced in the reply, then under Additional Options choose Manage Attachments. You can add photos from your computer, choose the ones you want in your post, then when done post. More instructions are here:

https://forums.offshoreelectrics.com...highlight=Post

.ERROR 403 - This is not the page you are looking for

Comment

-

Hello fluid, unfortunately there was no (manage attachments) in my advanced within reply. I read the link you sent as well but without the manage attachments I couldn?t even get started. I can?t even upload a screen shot but there was something about parse and email but nothing about manage attachmentsComment

-

No manage attachments found

There is only a ticked check box saying automatically parse links in texts. And then another check box ticked saying subscribe to this thread and notify me of changes and also a drop down box saying instantly using email and other choices within the drop box none of which are manage attachments also another choice rate this thread excellent and choices and that is the total under advanced.

I am replying from advanced so I could read and write what I see below exactly.Comment

-

No need to go advanced, there is a button at the top of the reply box 3rd from the right it looks like a painting of a tree in a picture frame and is called "insert image", click that and it brings up a pop up box, click "from computer" browse the file explorer to find your image, select your image, click "open" in the file explorer, click "upload file(s)" and it pastes into the reply a text link to the image it uploded from your computer.Paul Upton-Taylor, Greased Weasel Racing.Comment

-

-

IMG_2618.jpg IMG_2619.jpgThis first photo shows the rudder and prop location.this second photo shows the strut is just below the rear skis and level.The above previous 5 photos are the first photo shows the placement of the lipo esc motor etc the second shows the AOT s adjustable on the outer edge of the front boom tubes the third photo shows the COG The 4th photo shows the fin bend the 5th shows the more forward fin mounting in this photo you can see the U in the fin where it originally mounted around the boomComment

-

From the photos posted I don’t see anything grossly wrong with the setup. Most riggers are more sensitive to rudder inputs if the CG is well behind the center of the fin and they prefer the CG and fin to be nearly the same for neutral steering in a turn. I know the OP believes his boat behaves the opposite from this, which seems odd to me. My JAE rigger has the CG at about that location and the fin is about 1” ahead of the CG. It drives like an F1 car.

If the sponsons are digging in then they are either too narrow for the boat’s weight or their AOA is too shallow. The easiest fix is to increase the AOA by a couple degrees.

It isn’t possible from the photo to tell if the strut is parallel to the tub bottom. The OP may want to try lowering the strut to see if this helps or hurts his steering sensitivity. Are the rear sponsons out of the water when the rigger is at full speed?

Because his rudder hinge angle is adjustable, he can try moving the bottom of the rudder forward slightly - with the tub at the ride angle. This will take some weight off the sponsons in a turn and might reduce the risk of the sponson digging in.ERROR 403 - This is not the page you are looking for

Comment

Comment