Thanks Titu!

I have decided not to take the HPR... I'm not going to get much time to get on the water anyway... Oh well...

I will hit it when I get back....

On another positive note, I have found another lake with much more open water so after a little testing, I'me going to get myself over there to have some fun!

I have decided not to take the HPR... I'm not going to get much time to get on the water anyway... Oh well...

I will hit it when I get back....

On another positive note, I have found another lake with much more open water so after a little testing, I'me going to get myself over there to have some fun!

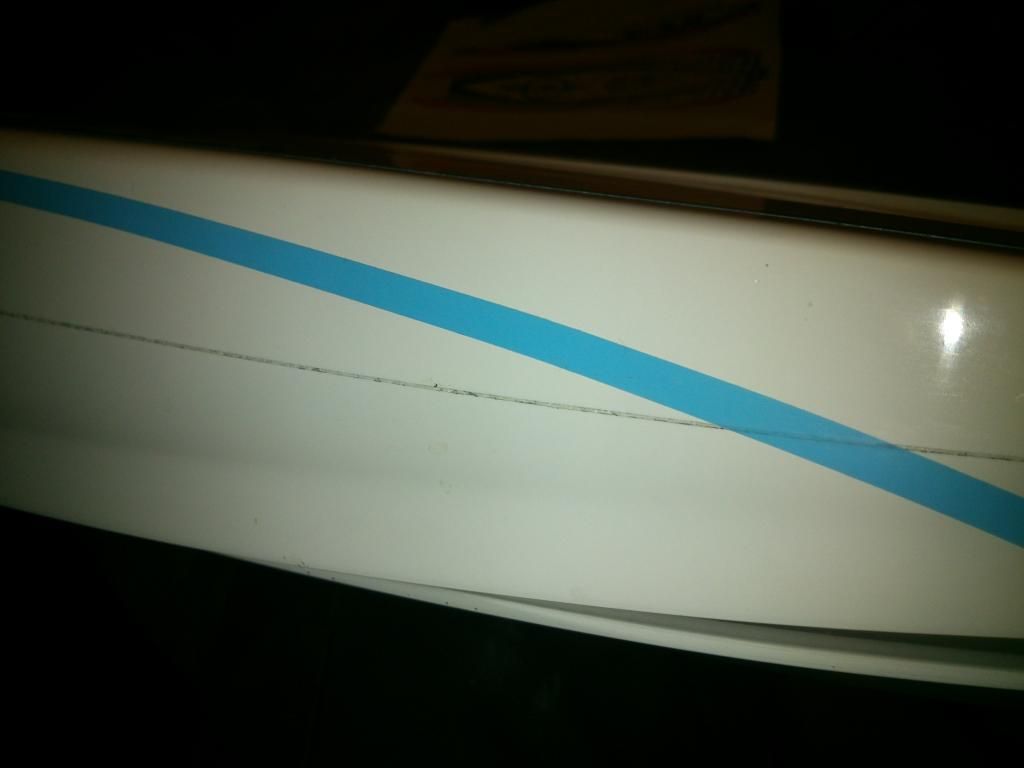

I would start with resin and microballons and fill the seam. What do you mean by the seam is sticking out? A photo would be great. My experience runs with fiberglass and metal so I hope some guys jump in that have been down this road and know the pitfalls to look out for.

I would start with resin and microballons and fill the seam. What do you mean by the seam is sticking out? A photo would be great. My experience runs with fiberglass and metal so I hope some guys jump in that have been down this road and know the pitfalls to look out for.

Comment