Here's the link for the drive. Scroll down about half way and you'll see it listed as drive system and the drive shaft(impeller) is right above it. The decoy drive is 15mm as opposed to 19mm for the mini jet. Overall the decoy drive is smaller than the mini jet. It is also better built than the mini. It appears to be a scaled down version of the Abc Hobby 22mm drive.

Mini-V w/decoy duck jet drive build

Collapse

X

-

Ahh, I thought they were using the 22mm drive in the duck too. Not sure how well a 15mm drive would perform in a jet sprint. I destroyed my stock impeller and made a new one, but was hoping to find a reliable source for parts because turning down a 27mm prop to 19mm and epoxying the whole thing together isn't very fun.Light travels faster than sound, so people may appear to be bright until you hear them speak.Comment

-

^^ I have the NQD drive, which is a knock off of the graupner one, but with a smaller shaft. Instead of pulling my existing bushing out of the drive and finding a shaft bushing for the stator, I'd rather just get the whole graupner drive. Unfortunately everyone is out of stock still Light travels faster than sound, so people may appear to be bright until you hear them speak.

Light travels faster than sound, so people may appear to be bright until you hear them speak.Comment

-

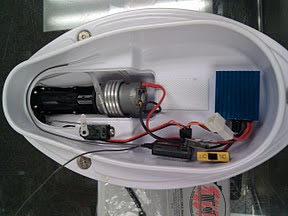

I finished painting it and started to assemble it yesterday. I decided to use the stock mini-v motor, rx/esc, and servo for it's maiden voyage. This will also let me see how a stock version performs vs. a brushless version which will be next. I used one of the connectors from R2 hobbies since the ones from Horizon aren't available until March. I used Shoe Goo to seal and glue the drive into the hull. I routed the cooling tubes using the parts from an Abc Hobby Jet ski. I had a homemade cooling coil from another project that I put on the motor and used a rx/esc mini-v unit that is already waterproofed and water cooled through the heatsink. This was from a Mini-v that I converted to brushless. Will be interested to see if I burn it on this set up or not. I know that they are only rated for 10amps and the duck one is a 30amp one. Might be smoking it but that's alright. Next to get the servo mounted (I already waterproofed it). Weight is now 336 grams, about 50 grams heavier than stock. Will be interested to see how low this one sits in the water and if all the leaks are plugged.

Comment

-

looks good

with what I've seen some people put that speedo through I don't think it'll smoke. the duck speedo was just something they had so they could put 2.4Ghz in, it's also a tug not a v.

they mounted the jet unit in the duck with silicone, the screws were just for show imo

I think a volere coupler might work

I'll post a build of my brushless duck as soon as I'm done with it

Comment

-

Thanks for posting the pic Geovw72. The coupler you showed might work but for your brushless motor (depending on the motor) the couple for the 22mm Abc Hobby jet ski would work. It's 3.17X 3mm. It just might have to be turned down to fit in the space available. Got the servo mounted and electrics tested to tomorrow I do a float and leak test and post a small vid. After that might be later in the week before I can go down to the creek for the maiden voyage. It's below 0 right now but will be warmer in a few days. Happy New Year everyone!

Comment

-

Tub Testing

First tub test yesterday was a bust. All electronics worked and drive but it leaked like a shower around transom. So sealed that up and tried today just one spot leaking so will have that fixed soon. See the vid. Watercooling also worked but is not very strong. I disconnected tubing from drive and it isn't pluged. May have to try removing the red ring from behind stator as that may be obstructing it some.

Comment

-

i think that the watercooling is going to be weak in a tub test. the way it works if from water coming through the jet. with the short burst of throtle you were giving it it doesnt have a chance to build enough presure. i am pretty sure once you get it on the water moving at speed for longet periods of time it will work better.see my fleet : http://forums.offshoreelectrics.com/...hp?albumid=294

: http://forums.offshoreelectrics.com/...hp?albumid=294Comment

-

i think that the watercooling is going to be weak in a tub test. the way it works if from water coming through the jet. with the short burst of throtle you were giving it it doesnt have a chance to build enough presure. i am pretty sure once you get it on the water moving at speed for longet periods of time it will work better.

the duck cooling exits where it enters so you never really "see" it, but it works. you may want to drill out the pickup larger, that's what I've been doing with mine. the read ring should also be indexed and fit behind the pickup. stock line was really small, but after running the duck for 10min on the stock pack the motor was as cold as the pond

Comment

-

I was thinking just what you said GeoVW. I'm sure that as long as there is water moving in the lines that it will cool. I think I'll wait until I go brushless to see weather it needs the larger intake before the nozzle. My red ring was also a little askew behind the stator. Straightened that out so we'll see. I'm too used the long stream coming out of the modded mini-jet drives or knock offs as well. Now that think about the 22mm never was very strong either.

the duck cooling exits where it enters so you never really "see" it, but it works. you may want to drill out the pickup larger, that's what I've been doing with mine. the read ring should also be indexed and fit behind the pickup. stock line was really small, but after running the duck for 10min on the stock pack the motor was as cold as the pond

Chuck E Cheese, thanks for your thoughts also. The one thing different with the jet drives is that the water goes through the tubing from the drive has long as the motor is running. You can see it best when you try boat surfing in a stream. The jet drive will always have water coming out even though the hull maybe static in its position on the stream. A prop driven boat doing the same thing with the hull static will only push a small amount if any water through the tubing. Just my observations on the creek.Comment

-

check these out very nice and almost silent with the rubber coupler and tale a lot of power....http://www.jet-drive.de/index.php?op...id=2&Itemid=17:canadaComment

-

my point was that water only comes through the jet when you are on the throtle. the way you were reving it seemed like it was presure for a few seconds, then no presure (throtle off) when it gets to the coil then "no presure". just my thinking. it isnt like a jet ski where the motor is always in gear and turning even at idle. i think when you let off the gas it may be leaking back twards the jet....see my fleet : http://forums.offshoreelectrics.com/...hp?albumid=294

: http://forums.offshoreelectrics.com/...hp?albumid=294Comment

-

thanks for the link tim v, but were looking for something in the 3mm range.

volere coupler works great

it is double set screwed so no shims or wobble.

I really think that the pickup needs drilled out to flow, everything stock on the duck was very very small and I think you may loose some pressure with larger line. I've been working on a "scrap" boat with one of the drives and drilled out to 3/32" with a brushless motor I can get 2" of water out the outlet in a tub at full tilt

Comment

-

Good to know that coupler works. I think the jet ski one that I have will also work, but I'll have to probably machine it some to make it fit.thanks for the link tim v, but were looking for something in the 3mm range.

volere coupler works great

it is double set screwed so no shims or wobble.

I really think that the pickup needs drilled out to flow, everything stock on the duck was very very small and I think you may loose some pressure with larger line. I've been working on a "scrap" boat with one of the drives and drilled out to 3/32" with a brushless motor I can get 2" of water out the outlet in a tub at full tilt

I've also wondered how the cooling would work with a brushless motor. But good to know that drilling it out helps. I might also try modifying the end of the intake with a dremel to give it more angle and see what that does.Comment

Comment