Hello FE friends,

I've taken a lot from this forum so I would like to try to give something back. This is not the most well documented build, nor am I an expert by any means. I stumbled though a lot of this, especially the carbon fiber work. This is my fifth boat build, first wood model build, and second time messing with carbon fiber (first time vacuum bagging). The only time I have worked with it before was putting an inlay in my DF Explorer, which turned out great functionally, but looks absolutely terrible ha ha. Tricky stuff to work with when you are inexperienced, I made many mistakes. Quickly learning though and already know I will be capable of much better work on future builds thanks to all the hard lessons learned.

Big shout out to Sam Hallstrom ( @sammyha ) for his build videos on this hull on YouTube. I watched every video a few times, thanks a lot sir! Huge help.

Specs

Hull: Zipp Kits JAE 21FE v2 33"

Motor: Leopard 4074 2.5Y 2000kv

ESC: Raider 150

Motor Mount: Carbon Fiber Heavy Duty 40mm

Collet: Speedmaster collet style coupler 5mm to 3/16" flex

Servo: DS 3120 20kg

Strut: Speedmaster 21 Hydro Flat Bottom

Rudder: Speedmaster Small Single Pickup w/short "L" Bracket

LiPo: 6s 6000mAh and 6s 4000mAh

Every part purchased from OSE website aside from LiPo's

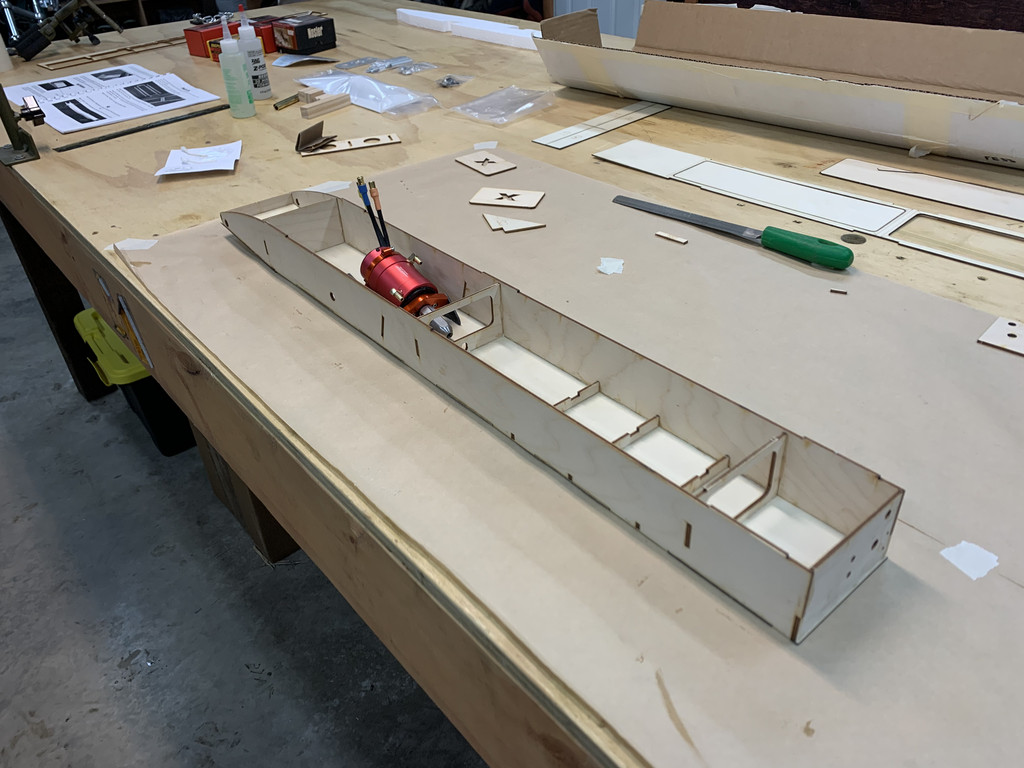

First mock up

Tub glued, and pool noodle foam cut into nose. Replaced battery tray supports with 1/8" thick pieces of ply in order to gain headroom for the big 6s 6000mAh packs. They juuust fit in this configuration.

Motor mount, battery tray and ESC tray in. Inside of tub sealed. I used the Zipp Kits battery tray for an ESC mount and an old fiberglass tray I had laying around for the LiPo

Tub wrapped and vacuum bagged. I just used a consumer grade food saver vacuum sealer for this task. Worked very well actually. Just have to be careful that all sharp edges are softened as to not puncture bag. I used industrial grade lay up material purchased from a composite supplier near home. Order is, Carbon cloth, peel ply, perforated release film, breather material. I could go on a long time about this process, there is lots of good information online. I just watched a few videos on YouTube and went for it.

Tub out of the bag. I realized right away that I messed up. I was dead set on wrapping the tub in one wrap so there would be minimal seams and maximum strength. This didn't work out so well, it was impossible to prevent it from creasing on the hard 90* corners. It's a challenging shape. Next time I would do this in two steps, one side at a time so there are only 2 corners to deal with at a time, I think this would allow you to pull the material tight to avoid creases in the corners.

Ended up sanding through the corners to get rid of the creases.

Reply With Quote

Reply With Quote

Bookmarks