Several years ago I promised my wife that I'd build her a big mahogany boat for the top of the piano. She's a patient lady! What got me off my duff was that she said I could buy a turbine... as soon as I got rid of a 4' cube of airplane kits and built her the boat I promised. Within 5 minutes both boys were assigned kits :) Last night I started on her boat.

The plans are Garry Finlay's, which you may find on the Astec Marine site. Garry sized them to fit nicely on E-sized paper. You can download the PDFs (2 pages) and have them printed for just a few dollars at Staples or Kinkos. Note that Garry is in the process of updating the plans as I find minor issues. They are fine for building - we're just working to make things perfect.

Full-Size Image

I began with a trued plywood base that is oversize for the boat. I added a straight centerline, then marked off the locations of each bulkhead.

Full-Size Image

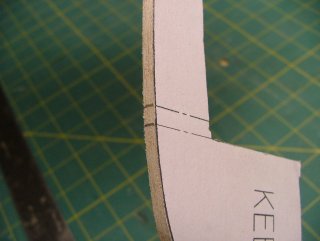

Then I used a triangle to make a pair of lines 3/16" apart (the thickness of the wood) across the width of the plank and labeled each pair of lines with the corresponding bulkhead letter.

So much for Monday night.

The plans are Garry Finlay's, which you may find on the Astec Marine site. Garry sized them to fit nicely on E-sized paper. You can download the PDFs (2 pages) and have them printed for just a few dollars at Staples or Kinkos. Note that Garry is in the process of updating the plans as I find minor issues. They are fine for building - we're just working to make things perfect.

Full-Size Image

I began with a trued plywood base that is oversize for the boat. I added a straight centerline, then marked off the locations of each bulkhead.

Full-Size Image

Then I used a triangle to make a pair of lines 3/16" apart (the thickness of the wood) across the width of the plank and labeled each pair of lines with the corresponding bulkhead letter.

So much for Monday night.

It ain't no Harbor Freight! I need it for ripping balsa stock in the future - an investment. All those good terms. I need a Forrester blade for it too - no sense having a good saw and using a $10 blade in it.

It ain't no Harbor Freight! I need it for ripping balsa stock in the future - an investment. All those good terms. I need a Forrester blade for it too - no sense having a good saw and using a $10 blade in it.

Comment