Nice idea on that tool! I always run into the same issue when removing servo arms.

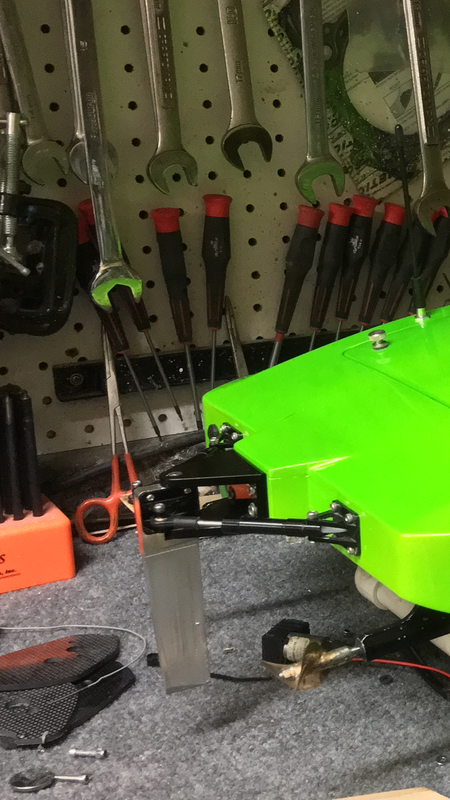

One thing about the rudder that I'd like to suggest is repositioning the turn horns on the sides so they are more inline with that main silver pivot pin. You can do that by simply flipping them from one side to the other and also moving them one hole backwards, then drill a new one and just epoxy the bolt in. This way you keep equal tension when rudder is straight as well as turned. Right now, if you turn the rudder fully to one side, you will notice the tension gets weaker on one pull cable than the other due to the horns actually shifting sideways in relation to the pivot point. Ideally, you want the horns to be perfectly inline with the bushing so they do not shift laterally.

Also, why do those stuffing tubes have such sharp bends? That's where the flexes will grind the tube most and create extra heat.

One thing about the rudder that I'd like to suggest is repositioning the turn horns on the sides so they are more inline with that main silver pivot pin. You can do that by simply flipping them from one side to the other and also moving them one hole backwards, then drill a new one and just epoxy the bolt in. This way you keep equal tension when rudder is straight as well as turned. Right now, if you turn the rudder fully to one side, you will notice the tension gets weaker on one pull cable than the other due to the horns actually shifting sideways in relation to the pivot point. Ideally, you want the horns to be perfectly inline with the bushing so they do not shift laterally.

Also, why do those stuffing tubes have such sharp bends? That's where the flexes will grind the tube most and create extra heat.

Comment